What is Battery Capacity Test and How Does it Work?

Battery capacity testing is a crucial procedure in assessing the performance and reliability of batteries used in various applications. This test involves measuring the amount of electrical energy a battery can store and subsequently deliver to a device. As technology evolves and the reliance on portable and sustainable energy sources grows, understanding battery capacity becomes increasingly significant.

What is a Battery Capacity Test?

A battery capacity test is a methodical process designed to evaluate the total charge a battery can hold and discharge over time. This measurement is typically expressed in milliampere-hours (mAh) or watt-hours (Wh). By conducting a battery capacity test, manufacturers, engineers, and consumers can determine how long a battery will power a device before needing a recharge or replacement. This test involves discharging the battery at a controlled rate and monitoring the amount of energy it delivers until it reaches a predefined cutoff voltage.

In essence, a battery capacity test aims to quantify the energy storage capability of a battery under specified conditions. The test procedure often includes fully charging the battery, then discharging it at a constant current or power level while recording the time taken to reach the cutoff voltage. The resulting data provides insights into the battery's efficiency, health, and potential longevity. This process helps identify any deviations from the expected performance, which could indicate issues such as capacity degradation, internal resistance increases, or other faults.

Battery capacity is a critical factor in numerous applications, impacting both performance and user satisfaction. In consumer electronics, such as smartphones and laptops, battery capacity determines the duration of use between charges, influencing the convenience and usability of these devices. For electric vehicles (EVs), battery capacity directly affects the driving range, which is a key consideration for consumers and manufacturers alike. A higher capacity typically translates to a longer range, reducing the frequency of recharging and enhancing the practicality of EVs.

In renewable energy storage systems, battery capacity is essential for balancing supply and demand. These systems rely on batteries to store excess energy generated from sources like solar panels and wind turbines, which can then be used when production is low or demand is high. Accurate knowledge of battery capacity ensures that energy storage solutions are designed and implemented effectively, contributing to the stability and efficiency of renewable energy infrastructures. Understanding battery capacity is fundamental to advancing technology and supporting the transition to sustainable energy solutions.

Purpose of Battery Capacity Testing

Battery capacity testing serves several important purposes, ensuring that batteries perform reliably, remain safe, and comply with industry standards. By thoroughly evaluating a battery's capacity, manufacturers and consumers can make informed decisions about battery usage and longevity, contributing to the overall efficiency and safety of the devices powered by these batteries.

1. Ensuring Performance and Reliability

One primary purpose of battery capacity testing is to ensure the performance and reliability of batteries. For manufacturers, accurate capacity measurements are crucial for quality control and product development. Knowing the exact capacity of a battery allows manufacturers to provide reliable specifications, which in turn helps consumers make informed purchasing decisions. For consumers, understanding battery capacity is essential for selecting products that meet their needs, particularly in terms of usage duration and recharging frequency. Consistent and accurate capacity testing helps ensure that batteries can deliver the expected performance over their intended lifespan, contributing to both longevity and efficiency.

2. Safety Concerns

Safety is another critical aspect addressed by battery capacity testing. Batteries that are not properly tested can pose significant safety risks, including overcharging and deep discharging, which can lead to overheating, leakage, or even explosions. Overcharging occurs when a battery is charged beyond its capacity, potentially causing excessive heat buildup and chemical reactions within the battery. Deep discharging, on the other hand, can damage the battery's internal structure and reduce its overall lifespan. By conducting thorough capacity tests, potential safety hazards can be identified and mitigated, ensuring that batteries operate within safe parameters and reducing the risk of accidents.

3. Regulatory Compliance

Battery capacity testing also plays a vital role in meeting regulatory compliance. Various industries have established standards and regulations to ensure the safety, reliability, and environmental impact of batteries. These standards often specify the acceptable ranges for battery capacity, performance, and safety characteristics. Compliance with these regulations is essential for manufacturers to legally market their products and for consumers to trust the safety and reliability of the batteries they use. Capacity testing helps manufacturers adhere to these standards, providing a level of assurance that their products meet the necessary requirements. This regulatory compliance is important for maintaining market integrity and protecting both users and the environment.

Types of Batteries Tested

Battery capacity testing encompasses a wide range of battery types, each serving different purposes and applications. Understanding the differences between primary and secondary batteries is essential for conducting appropriate capacity tests and ensuring optimal performance and safety.

1. Primary Batteries

Primary batteries, also known as non-rechargeable batteries, are designed for single-use applications. Once depleted, these batteries cannot be recharged and must be replaced. Common examples of primary batteries include alkaline and zinc-carbon batteries. Alkaline batteries are widely used in household items such as remote controls, flashlights, and toys due to their relatively high energy density and long shelf life. Zinc-carbon batteries, while less energy-dense than alkaline, are often found in low-drain devices like clocks and radios. Capacity testing for primary batteries focuses on determining the total energy available from the battery before it is exhausted. This helps manufacturers ensure consistent quality and performance, and allows consumers to choose batteries that meet their specific needs for duration and reliability.

2. Secondary Batteries

Secondary batteries, or rechargeable batteries, are designed for multiple charge-discharge cycles, making them suitable for applications where frequent battery replacement would be impractical or costly. Common examples of secondary batteries include lithium-ion, nickel-metal hydride (NiMH), and lead-acid batteries. Lithium-ion batteries are prevalent in portable electronics such as smartphones, laptops, and electric vehicles due to their high energy density, lightweight, and long cycle life. NiMH batteries are often used in applications such as digital cameras and cordless phones, offering a balance between capacity and environmental friendliness. Lead-acid batteries are typically used in automotive and industrial applications due to their robustness and reliability under high-load conditions.

Capacity testing for secondary batteries is crucial for evaluating their performance over repeated cycles of charging and discharging. This testing helps identify any degradation in capacity over time, which can affect the battery's efficiency and longevity. By understanding the capacity retention and cycle life of secondary batteries, manufacturers can optimize their products for specific applications, and consumers can make informed decisions about battery maintenance and replacement. Moreover, accurate capacity testing supports the development of more efficient and sustainable rechargeable battery technologies, contributing to advancements in various fields.

Methods of Battery Capacity Testing

Several methods are employed to test battery capacity, each with its own process, advantages, and limitations. These methods provide critical data on how well a battery can store and deliver energy, which is essential for assessing performance, reliability, and safety.

1. Constant Current Discharge Test

The constant current discharge test is one of the most common methods used to measure battery capacity. In this test, a battery is discharged at a fixed current until it reaches a predefined cutoff voltage. The time taken to reach this cutoff voltage is recorded, and the capacity is calculated as the product of the discharge current and time. This method is straightforward and provides a clear measurement of the battery's ability to deliver a steady current over time.

The benefits of the constant current discharge test include its simplicity and ease of implementation. It provides reliable and repeatable results, making it suitable for standard battery evaluations. However, this method has limitations, as it does not account for variations in power demand that occur in real-world applications. Additionally, it may not accurately reflect the performance of batteries under fluctuating load conditions.

2. Constant Power Discharge Test

The constant power discharge test involves discharging the battery at a constant power level rather than a constant current. This method simulates conditions where the power demand remains steady, which can be more representative of certain applications, such as those involving electronic devices or electric vehicles. During the test, the current is adjusted continuously to maintain constant power as the battery voltage decreases.

This method is effective in providing a more realistic assessment of battery performance under actual usage conditions. It is particularly useful for applications where power demand is relatively constant. However, the constant power discharge test can be more complex to perform and requires precise control and monitoring equipment. It may also be less applicable for batteries used in scenarios with highly variable power requirements.

3. Impedance Spectroscopy

Impedance spectroscopy is a technique used to measure the internal resistance and electrochemical processes within a battery. This method involves applying an alternating current (AC) signal of varying frequencies to the battery and measuring the resulting voltage response. The data obtained provides insights into the battery's impedance, which is related to its capacity, health, and state of charge.

The advantages of impedance spectroscopy include its ability to diagnose issues such as capacity fade, internal short circuits, and other defects that may not be apparent through simple discharge tests. It can provide a comprehensive assessment of battery health and help identify degradation mechanisms. However, impedance spectroscopy requires specialized equipment and expertise, making it more complex and potentially costlier than other methods.

4. Coulomb Counting

Coulomb counting is a method that involves tracking the charge and discharge currents of a battery over time to calculate its capacity. By integrating the current over the charge and discharge cycles, the total charge transferred in and out of the battery can be measured, providing an estimate of the battery's capacity.

This method is accurate and useful for applications where precise monitoring of battery usage is required, such as in electric vehicles and energy storage systems. Coulomb counting can provide real-time data on battery capacity and state of charge. However, it is sensitive to measurement errors and requires high-precision current sensing and data logging equipment. Drift and cumulative errors over time can also affect accuracy, necessitating periodic recalibration.

Each of these methods offers unique insights into battery capacity and performance, and the choice of method depends on the specific requirements of the application and the type of battery being tested. By employing these testing techniques, manufacturers and users can ensure that batteries meet the necessary standards and perform reliably in their intended applications.

Steps in Conducting a Battery Capacity Test

Conducting a battery capacity test involves a systematic approach to ensure accurate and reliable results. The process can be broken down into several key steps: preparation, discharge phase, recording data, and analysis. Each step is crucial for obtaining a comprehensive understanding of the battery's capacity and performance.

1. Preparation

The first step in conducting a battery capacity test is preparation. This involves ensuring that the battery is fully charged to its maximum capacity, as starting with a fully charged battery is essential for obtaining accurate capacity measurements. Charging should be done according to the manufacturer’s specifications, using appropriate charging equipment to avoid any damage or safety issues.

Next, the testing equipment must be set up. This includes configuring the battery tester or analyzer, connecting the battery securely, and calibrating the equipment to ensure precise measurements. The environment should be controlled to maintain a consistent temperature, as temperature variations can affect battery performance and test results. Proper preparation ensures that the test conditions are stable and reproducible, providing a solid foundation for the subsequent steps.

2. Discharge Phase

During the discharge phase, the battery is discharged under controlled conditions. This can be done by applying a constant current or constant power, depending on the chosen testing method. The discharge should be carried out until the battery reaches its predefined cutoff voltage, which is typically specified by the manufacturer.

Throughout the discharge phase, it is important to monitor the battery's voltage and temperature. Voltage measurements help determine the point at which the battery reaches its cutoff voltage, while temperature monitoring ensures that the battery does not overheat, which could lead to inaccurate results or safety hazards. Maintaining stable discharge conditions is critical for obtaining accurate capacity measurements.

3. Recording Data

Recording data accurately is essential for calculating the battery’s capacity. During the discharge phase, the time taken for the battery to reach the cutoff voltage is measured. This time, combined with the discharge current or power, is used to calculate the battery's capacity.

For instance, in a constant current discharge test, the capacity is calculated by multiplying the discharge current (in amperes) by the time (in hours) taken to reach the cutoff voltage, resulting in a measurement in milliampere-hours (mAh). In a constant power discharge test, the capacity is calculated by integrating the power over time, yielding a measurement in watt-hours (Wh). Accurate data recording is crucial for reliable capacity calculations.

4. Analysis

The final step is analyzing the recorded data. The calculated capacity is compared to the manufacturer’s specifications to determine if the battery meets the expected performance criteria. This comparison helps identify any deviations from the nominal capacity, which could indicate issues such as capacity degradation, internal resistance increases, or other faults.

Additionally, the analysis can reveal trends over multiple charge-discharge cycles, providing insights into the battery's longevity and reliability. Identifying patterns of degradation or anomalies can help diagnose potential problems and inform maintenance or replacement decisions. Thorough analysis ensures that the battery’s performance is fully understood and that any issues are promptly addressed.

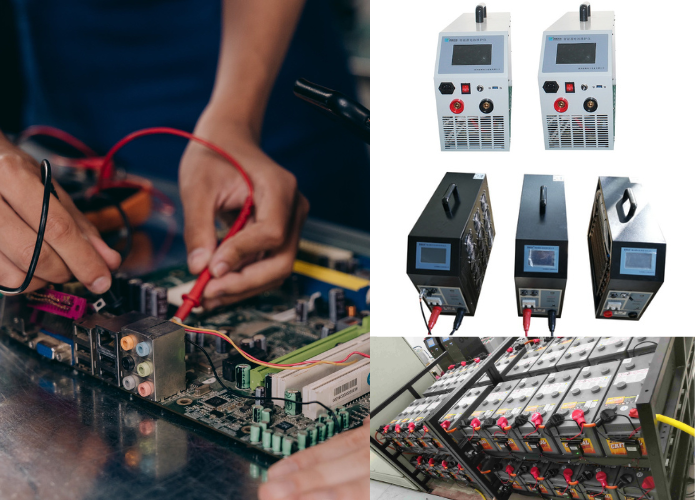

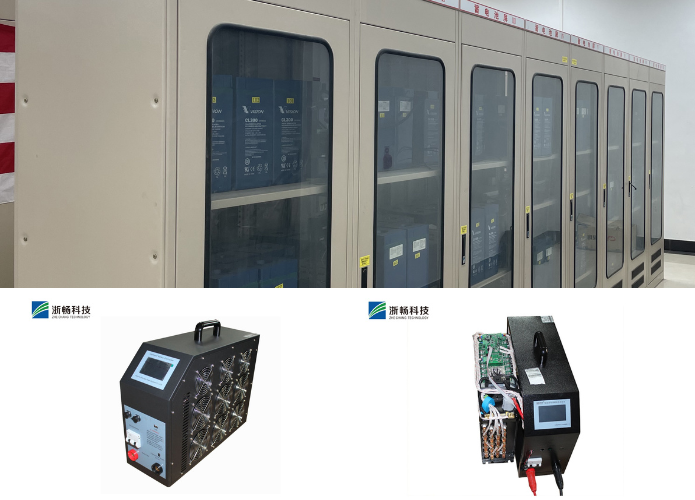

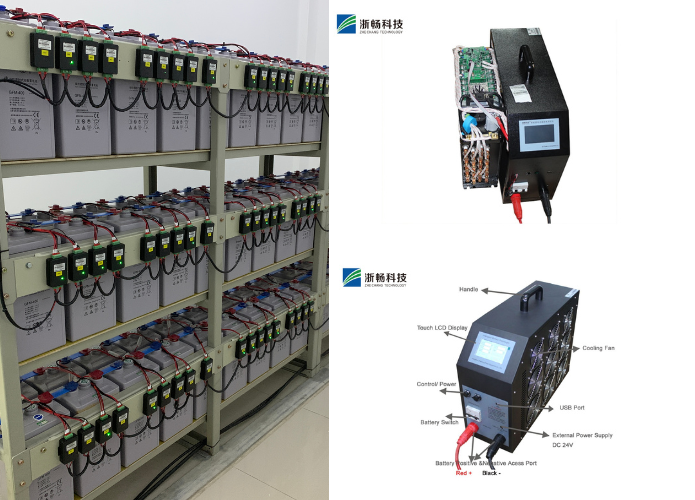

Equipment Used in Battery Capacity Testing

Battery capacity testing relies on various types of equipment to ensure accurate and reliable measurements. Each piece of equipment plays a specific role in the testing process, from controlling discharge conditions to recording and analyzing data. Understanding the features and capabilities of this equipment is crucial for conducting effective battery capacity tests.

1. Battery Analyzers

Battery analyzers are specialized devices designed to test and evaluate the performance of batteries. These analyzers can measure key parameters such as voltage, current, capacity, internal resistance, and state of charge. They often come with features like programmable discharge rates, automated testing routines, and safety cutoffs to prevent over-discharge or overheating. Battery analyzers are versatile and can handle various types of batteries, making them essential for both laboratory and field testing.

The capabilities of battery analyzers extend to providing detailed diagnostic information, which helps in identifying potential issues like capacity fade or internal shorts. They can also simulate real-world usage scenarios, providing insights into how a battery will perform under different conditions. Overall, battery analyzers are indispensable for comprehensive battery evaluation and capacity testing.

2. Load Banks

Load banks are used to simulate different discharge conditions by applying a controlled load to the battery. They can create constant current, constant power, or variable load profiles, depending on the test requirements. Load banks are crucial for replicating the operational conditions a battery might encounter in its actual application, such as the varying loads experienced by batteries in electric vehicles or renewable energy systems.

By using load banks, testers can ensure that the battery's performance is evaluated under realistic conditions, providing more accurate and relevant capacity measurements. Load banks are also useful for stress testing batteries to understand their limits and behavior under high-load scenarios. This information is vital for assessing the reliability and safety of batteries in demanding applications.

3. Multimeters and Data Loggers

Multimeters and data loggers play a vital role in accurately measuring and recording voltage, current, and temperature during battery capacity tests. Multimeters provide precise real-time measurements, which are essential for monitoring the battery's status throughout the discharge phase. Data loggers, on the other hand, continuously record these measurements over time, allowing for detailed analysis of the battery's performance.

The importance of multimeters and data loggers lies in their ability to capture accurate and consistent data, which is critical for calculating battery capacity and identifying any anomalies. They enable testers to maintain a comprehensive record of the test conditions and results, facilitating a thorough evaluation of the battery's characteristics and performance.

4. Software Tools

Software tools are used to analyze and visualize the data collected during battery capacity tests. These tools can process large volumes of data, generating detailed reports and graphs that illustrate the battery's performance over time. Features like trend analysis, comparative studies, and predictive modeling help in understanding the long-term behavior of batteries and identifying potential issues early.

By using software tools, testers can gain deeper insights into the battery's capacity, efficiency, and health. These tools enhance the analysis process by providing intuitive visual representations of the data, making it easier to interpret complex results and make informed decisions. Software tools are integral to modern battery testing, enabling comprehensive and efficient data analysis.

Factors Affecting Battery Capacity Test Results

Several factors can influence the results of battery capacity tests, affecting the accuracy and reliability of measurements. Understanding these factors is crucial for interpreting test data correctly and ensuring that the performance of batteries is accurately assessed.

1. Temperature

Temperature has a significant impact on battery performance and capacity. Both ambient temperature and the temperature of the battery itself can affect the chemical reactions and internal resistance within the battery. As temperature increases, the electrolyte viscosity decreases, which can improve ion mobility and increase capacity temporarily. However, higher temperatures can also accelerate chemical reactions and lead to faster degradation over time. Conversely, colder temperatures can reduce battery performance, slowing down chemical reactions and lowering capacity. Maintaining a consistent temperature during capacity testing is essential for obtaining reliable and repeatable results.

2. Discharge Rate

The discharge rate, or the rate at which energy is drawn from the battery during testing, can influence capacity measurements. Batteries often exhibit different capacities at different discharge rates. Higher discharge rates typically result in lower measured capacities due to increased internal resistance and voltage drop under load. Conversely, lower discharge rates may yield higher capacities as the battery is able to maintain a more stable voltage output over a longer period. Understanding the relationship between discharge rate and capacity is important for selecting appropriate testing conditions that reflect real-world usage scenarios.

3. Battery Age and Cycle Count

The age of a battery and the number of charge-discharge cycles it has undergone can significantly affect its capacity. Over time, chemical reactions within the battery can lead to degradation of electrode materials, increased internal resistance, and loss of active materials. This degradation is accelerated by the number of cycles the battery has experienced, particularly in rechargeable batteries like lithium-ion and nickel-metal hydride. Capacity tests conducted on aged batteries may show reduced capacities compared to new batteries, reflecting the cumulative effects of aging and cycling on battery performance.

4. State of Charge (SOC)

The initial state of charge (SOC) of the battery at the beginning of the capacity test can impact the test results. Batteries discharged to lower SOC levels may exhibit lower capacities due to irreversible chemical changes that occur at low states of charge. Similarly, batteries charged to higher SOC levels may show inflated capacities that do not accurately represent their performance under typical usage conditions. Maintaining a standardized SOC for all batteries tested helps ensure consistency and comparability of capacity measurements across different tests and battery types.

Interpreting Test Results

Interpreting battery capacity test results involves analyzing the data obtained from testing to understand the battery's performance, reliability, and potential issues. Several key aspects need to be considered to draw meaningful conclusions from capacity test results.

1. Understanding Capacity Ratings

Battery capacity ratings indicate the amount of energy a battery can store and deliver under specific conditions. Measured in milliampere-hours (mAh) or watt-hours (Wh), capacity ratings provide insights into how long a battery can power a device before needing recharging. Higher capacity ratings generally indicate longer runtime and better performance. Understanding the measured capacity involves comparing it to the battery's nominal capacity (as specified by the manufacturer) and assessing how closely the measured capacity aligns with expectations. Significant deviations may indicate variations in manufacturing quality, battery degradation, or inaccuracies in testing procedures.

2. Comparing to Standards

Battery capacity test results are often compared against industry standards and benchmarks to determine whether the battery meets established performance criteria. Standards may specify acceptable ranges for capacity, internal resistance, cycle life, and safety parameters. Comparing test results to these standards helps assess whether the battery meets regulatory requirements and user expectations. A pass or fail determination is typically based on how closely the measured capacity and other performance metrics align with the specified standards. Deviations from standards may prompt further investigation into potential causes, such as manufacturing defects, aging, or improper handling.

3. Diagnosing Issues

Interpreting battery capacity test results involves diagnosing potential issues that may affect performance or longevity. Reduced capacity compared to nominal ratings can indicate various underlying problems, such as electrode degradation, electrolyte depletion, or internal shorts. Diagnosing these issues requires a systematic analysis of test data, including voltage profiles, temperature variations, and discharge curves. Identifying the root causes of reduced capacity helps in understanding the battery's health status and making informed decisions regarding maintenance, replacement, or operational adjustments.

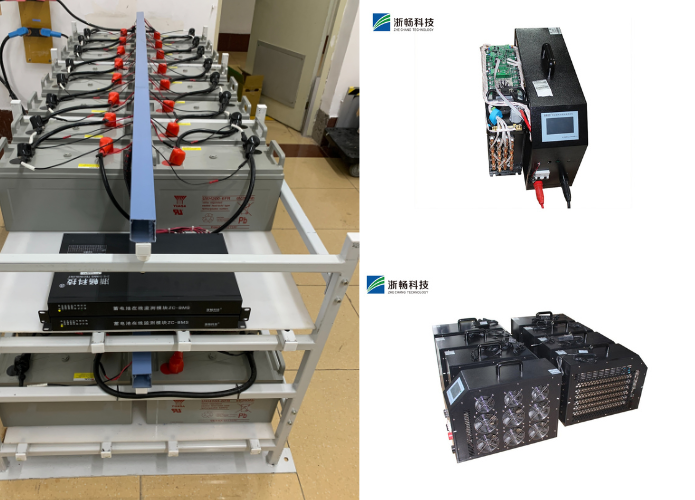

Applications of Battery Capacity Testing

Battery capacity testing plays a critical role across various industries and applications, ensuring reliable performance, safety, and efficiency of battery-powered systems and devices. Understanding the specific applications of battery capacity testing highlights its importance in different sectors.

1. Consumer Electronics

In consumer electronics, battery capacity testing ensures that devices such as smartphones, laptops, tablets, and wearable gadgets perform reliably over their expected lifespan. Capacity testing helps manufacturers determine the runtime and recharge intervals of batteries under typical usage conditions. This information is crucial for consumers who rely on these devices for everyday tasks, ensuring they can make informed decisions based on battery performance and longevity.

2. Electric Vehicles

Battery capacity testing is essential for electric vehicles (EVs) to accurately estimate driving range and monitor battery health. EV manufacturers and service providers use capacity tests to assess battery performance under various driving conditions and charging cycles. Capacity testing helps in predicting and managing battery degradation over time, optimizing the efficiency and reliability of EVs. Accurate range estimation based on capacity testing is crucial for enhancing consumer confidence and promoting wider adoption of electric vehicles.

3. Renewable Energy Systems

In renewable energy systems, such as solar and wind power installations, battery capacity testing plays a vital role in storage efficiency and lifecycle management. Batteries store excess energy generated during peak production periods for use during low production or high demand periods. Capacity testing ensures that batteries can store and deliver energy effectively over their operational lifespan. It helps renewable energy operators optimize energy storage strategies, minimize system downtime, and maximize overall efficiency of energy conversion and utilization.

4. Industrial and Medical Equipment

Battery capacity testing is critical in industrial and medical equipment to ensure uninterrupted operation and safety. Industrial machinery, emergency backup systems, and medical devices rely on batteries to maintain functionality during power outages or critical operations. Capacity testing helps verify that batteries can meet the stringent reliability and safety requirements of these applications. It ensures that batteries perform as expected under high-load conditions, safeguarding operations and minimizing risks associated with power failures.

Conclusion

In conclusion, battery capacity testing is a fundamental process that spans across multiple industries and applications, ensuring the performance, reliability, and safety of battery-powered devices and systems. By evaluating the ability of batteries to store and deliver energy effectively, capacity testing provides crucial insights into their operational capabilities and longevity.

In consumer electronics, capacity testing helps manufacturers and consumers alike understand battery performance metrics, such as runtime and recharge intervals, ensuring devices meet expectations for reliability and usability. In electric vehicles, capacity testing plays a pivotal role in estimating driving range accurately and monitoring battery health over time, supporting the adoption and efficiency of sustainable transportation solutions.

For renewable energy systems, capacity testing optimizes energy storage strategies, enhancing the efficiency of solar and wind power installations by ensuring batteries can store and deliver energy reliably. In industrial and medical equipment, capacity testing ensures uninterrupted operation and safety, critical for maintaining essential services and patient care in healthcare settings.

Overall, battery capacity testing enables stakeholders to make informed decisions regarding battery selection, maintenance, and replacement, ultimately contributing to improved efficiency, sustainability, and safety across diverse industries. As technology advances and energy demands evolve, the role of capacity testing remains indispensable in driving innovation and ensuring the continued reliability of battery-powered solutions.

Popular Battery Tester

Popular Battery Tester

Latest News

Latest News

Get Price of Battery Tester

Get Price of Battery Tester

Address:

Floor 3, Building 1, No.1418-60, Moganshan road, Hangzhou city, Zhejiang Province, China.310015