New Energy Era: The Criticality of Electric Vehicle Battery Testing

Introduction to the New Energy Era

The automotive industry is undergoing a radical transformation as the world shifts towards sustainable energy solutions. Traditional internal combustion engine (ICE) vehicles are gradually being replaced by electric vehicles (EVs), driven by growing concerns over climate change, carbon emissions, and fossil fuel dependency. Governments worldwide are implementing policies to phase out gasoline and diesel-powered cars, and consumers are increasingly opting for greener alternatives.

At the heart of this transformation lies the EV battery—an essential component that determines an electric vehicle's range, efficiency, safety, and overall performance. Unlike conventional fuel tanks, EV batteries require sophisticated management and testing to ensure they function optimally over their lifespan. Without rigorous testing, issues such as overheating, degradation, and safety hazards could hinder the widespread adoption of EVs.

Battery testing is, therefore, a critical aspect of the EV revolution. It ensures that batteries meet stringent safety and performance standards, supporting the industry's growth and consumer trust. This blog will explore the significance of EV battery testing, the methodologies involved, and the impact of testing on the future of sustainable transportation.

Types of Batteries Used in Electric Vehicles

Electric vehicles utilize different battery chemistries, each offering specific advantages and limitations. The most commonly used batteries include:

Lithium-Ion (Li-Ion) Batteries

Currently, lithium-ion batteries dominate the EV market due to their high energy density, long lifespan, and efficiency. However, different lithium-ion battery variants exist, including:

- Lithium Iron Phosphate (LiFePO4)–Known for its thermal stability, long cycle life, and enhanced safety, but has lower energy density than other lithium-ion chemistries.

- Lithium Nickel Manganese Cobalt Oxide (NMC)–Offers a balance of high energy density, long life, and affordability, making it a popular choice for modern EVs.

- Lithium Cobalt Oxide (LCO)–High energy density but more expensive and less stable, mainly used in consumer electronics rather than EVs.

Nickel-Metal Hydride (NiMH) Batteries

Commonly found in hybrid vehicles, NiMH batteries offer good energy capacity and safety but suffer from high self-discharge rates and lower efficiency than lithium-ion alternatives.

Solid-State Batteries

An emerging technology, solid-state batteries replace liquid electrolytes with solid electrolytes, improving safety, energy density, and charge speeds. While still in the research and development phase, these batteries are expected to revolutionize EV performance.

Different battery types require tailored testing methods to assess their efficiency, safety, and longevity before deployment in electric vehicles.

Key Objectives of EV Battery Testing

EV battery testing is conducted with several critical objectives in mind:

- Performance Optimization–Ensuring that batteries provide the expected energy output, charge retention, and power delivery.

- Safety Assurance–Identifying potential failure points, such as overheating, short circuits, and internal defects, that could lead to hazardous situations.

- Longevity Prediction–Assessing how batteries degrade over time and under various charging and discharging cycles to determine their expected lifespan.

- Regulatory Compliance–Ensuring that batteries meet national and international safety and environmental regulations.

- Extreme Condition Evaluation–Testing how batteries perform under high temperatures, freezing conditions, and physical stress.

By fulfilling these objectives, battery testing helps manufacturers produce reliable, high-performance EVs that consumers can trust.

Essential Testing Parameters for EV Batteries

When evaluating EV batteries, several key parameters are tested to determine their efficiency and safety:

- Capacity Testing–Measures the total charge a battery can hold and how it changes over time.

- Internal Resistance–High internal resistance can lead to excessive heat generation and reduced efficiency.

- Cycle Life Testing–Evaluates how many charge-discharge cycles a battery can undergo before significant performance degradation.

- Voltage Stability–Ensures that the battery delivers consistent voltage levels under varying loads.

- Thermal Management Efficiency–Examines the effectiveness of cooling systems in maintaining optimal operating temperatures.

- Self-Discharge Rate–Determines how quickly a battery loses charge when not in use.

These parameters are crucial in ensuring that EV batteries provide reliable and safe performance over their lifespan.

Advanced Testing Techniques for EV Batteries

With advancements in battery technology, modern testing techniques have evolved to ensure accuracy and efficiency:

- Electrochemical Impedance Spectroscopy (EIS)–Measures internal resistance and detects early signs of battery aging.

- X-ray Computed Tomography (X-ray CT)–Provides detailed imaging of battery internals to detect manufacturing defects.

- Accelerated Aging Tests–Simulates years of battery usage in a short period to predict long-term performance.

- Smart Battery Testing with AI–Utilizes machine learning algorithms to monitor real-time data and predict battery failures.

These sophisticated methods help manufacturers optimize battery design and improve reliability.

Role of Battery Testing in Electric Vehicle Safety

Safety is one of the most critical aspects of EV battery testing. Without proper testing, batteries can pose significant risks, including:

- Thermal Runaway–A dangerous reaction where excessive heat leads to battery failure or fire.

- Short Circuits–Can result from internal defects, leading to overheating and potential explosions.

- Mechanical Damage Resistance–Ensures that batteries can withstand shocks, vibrations, and impacts.

Testing ensures that EV batteries meet stringent safety standards, reducing the risk of catastrophic failures.

Testing for Extreme Conditions

EV batteries must function reliably across diverse environments, requiring specialized extreme condition tests:

- High-Temperature Testing–Ensures batteries operate safely in hot climates.

- Cold Weather Testing–Measures battery performance at freezing temperatures.

- Vibration and Shock Testing–Simulates road conditions to evaluate durability.

- Crush and Impact Tests–Determines how well batteries withstand collisions.

These tests help ensure that EVs remain reliable regardless of where they are used.

EV Battery Testing Standards and Regulations

Regulatory standards ensure battery safety and efficiency. Key regulations include:

- UN 38.3 – Governs battery transport safety.

- SAE J2464 – Defines abuse testing for lithium-ion batteries.

- ISO 12405 – Covers performance and reliability testing for EV batteries.

Adherence to these standards is crucial for manufacturers to ensure global compliance.

Emerging Technologies in EV Battery Testing

Advancements in technology are shaping the future of battery testing:

AI-Powered Testing – Uses machine learning to detect failures before they happen.

Blockchain for Battery Tracking – Enhances transparency in battery lifecycle management.

Quantum Battery Research – Exploring new ways to improve energy storage.

These innovations will further enhance battery reliability and performance.

Impact of Battery Testing on EV Market Growth

Reliable battery testing is essential for the success of the EV industry. By ensuring safe and efficient batteries, testing:

Increases consumer confidence.

Enables manufacturers to optimize costs.

Supports government regulations for safer EV adoption.

Battery testing plays a direct role in the expansion of the EV market.

Battery Recycling and Second-Life Testing

As EV adoption grows, the need for sustainable battery disposal increases. Testing plays a vital role in:

Assessing Second-Life Applications: Determining if used batteries can be repurposed for energy storage.

Evaluating Recycling Efficiency: Ensuring valuable materials like lithium, cobalt, and nickel are recoverable.

Reducing Environmental Impact: Preventing hazardous waste disposal through proper end-of-life assessments.

Future Challenges and Opportunities in EV Battery Testing

While advancements in battery testing continue, several challenges remain:

Standardization Across Regions: Variations in testing regulations create compliance complexities.

Scalability of Testing Facilities: Growing EV demand requires expansion of testing infrastructure.

Integration of New Chemistries: Emerging battery technologies like solid-state batteries demand new testing methodologies.

Reducing Testing Costs: Developing cost-effective yet accurate testing solutions remains a priority.

Opportunities lie in AI-driven automation, real-time monitoring, and enhanced regulatory collaboration to streamline testing processes.

Conclusion: The Critical Role of Battery Testing in the EV Revolution

EV battery testing is a cornerstone of the electric vehicle revolution. It ensures safety, enhances performance, and builds consumer trust in a rapidly expanding market. As battery technology evolves, testing methodologies must adapt to keep pace with innovations. Investing in advanced testing solutions will be key to unlocking the full potential of EVs and driving the world towards a sustainable energy future.

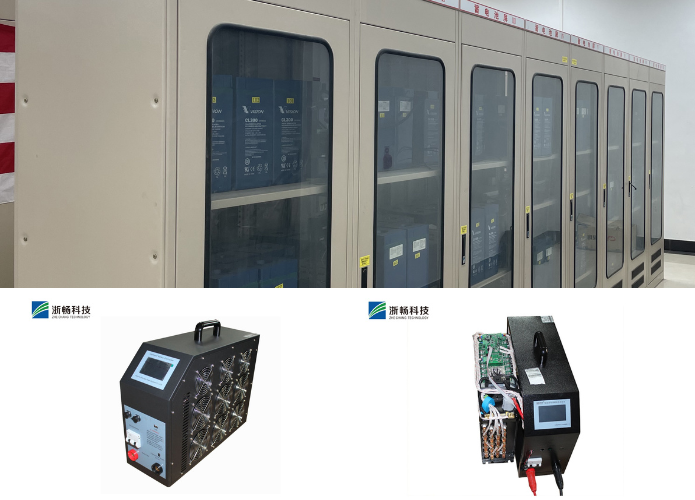

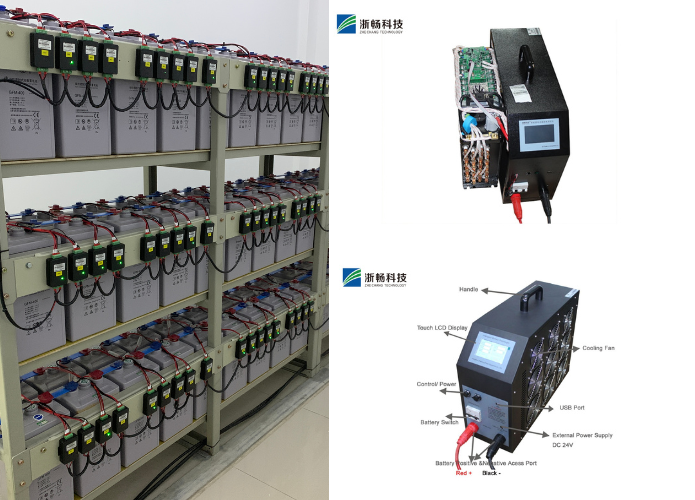

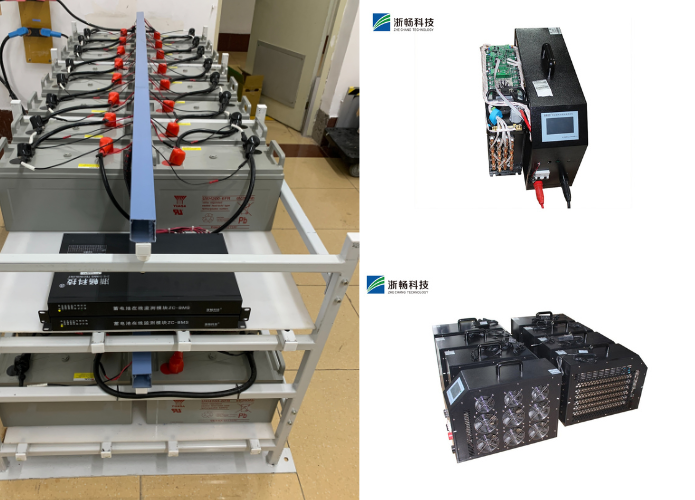

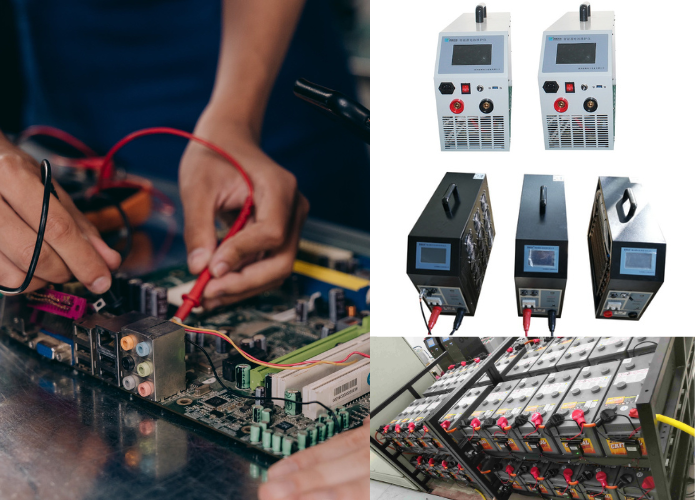

Popular Battery Tester

Popular Battery Tester

Latest News

Latest News

Get Price of Battery Tester

Get Price of Battery Tester

Address:

Floor 3, Building 1, No.1418-60, Moganshan road, Hangzhou city, Zhejiang Province, China.310015