How to Test Lithium Battery Capacity?

Testing the capacity of a lithium battery is an essential procedure to ensure its longevity, efficiency, and safety. Lithium batteries are widely used in various applications, from smartphones to electric vehicles, and their performance is critical. Understanding how to test lithium battery capacity can help you maintain your batteries in optimal condition. This guide will walk you through the process, the tools required, and the best practices for accurate testing.

Understanding Lithium Battery Capacity

Before diving into the testing methods, it's important to understand what lithium battery capacity means. The capacity of a lithium battery is the amount of charge it can hold, usually measured in milliamp-hours (mAh) or ampere-hours (Ah). This value indicates how long the battery can power a device before needing a recharge. Over time, the capacity of a lithium battery decreases due to factors such as age, usage patterns, and environmental conditions.

Why Testing Lithium Battery Capacity Is Important

Testing the capacity of your lithium battery is crucial for several reasons:

Performance Monitoring: Regularly testing your battery helps monitor its performance and predict when it might need replacement.

Safety: A battery that can no longer hold a charge effectively may overheat or even fail, posing safety risks.

Efficiency: Knowing the capacity of your battery ensures that you are using it within its optimal range, maximizing its lifespan.

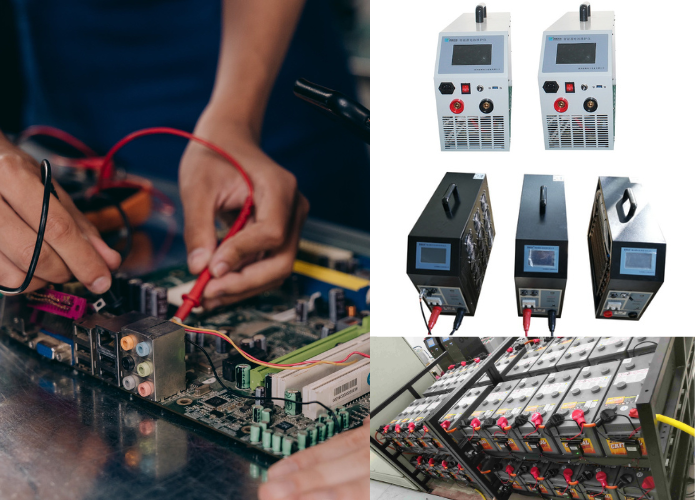

Tools Needed to Test Lithium Battery Capacity

To test the capacity of a lithium battery, you will need the following tools:

Lithium Battery Capacity Tester: This is the primary tool used to measure the battery's capacity. It discharges the battery while measuring the amount of charge removed, allowing you to calculate the total capacity.

Multimeter: A multimeter can measure voltage and current, which are essential for manual capacity calculations.

Battery Charger: Before testing, you need to ensure that the battery is fully charged.

Load Resistor: A resistor is used to simulate the load during the discharge process, which is crucial for an accurate test.

Step-by-Step Guide to Testing Lithium Battery Capacity

Lithium batteries are widely used in various applications, from smartphones and laptops to electric vehicles and renewable energy storage systems. Knowing the capacity of a lithium battery is essential for determining its health and performance. The capacity of a battery is typically measured in milliampere-hours (mAh) or ampere-hours (Ah), which indicates the amount of charge the battery can hold and deliver over a specified period. This guide will walk you through the step-by-step process of testing a lithium battery's capacity, ensuring that you obtain accurate and reliable results.

Step 1: Fully Charge the Battery

The first step in testing the capacity of a lithium battery is to ensure that it is fully charged. A fully charged battery allows you to measure its maximum capacity accurately.

Why Full Charging is Crucial

Lithium batteries have a specific voltage range within which they operate efficiently. Charging the battery to 100% ensures that it reaches its maximum voltage, allowing for an accurate capacity test. If the battery is not fully charged, the test will only measure the capacity from the current state of charge to the cutoff voltage, leading to inaccurate results. Therefore, it is crucial to use a charger that is compatible with your specific lithium battery type, whether it's a Lithium-Ion (Li-ion), Lithium Polymer (LiPo), or Lithium Iron Phosphate (LiFePO4) battery.

Charging Process

To charge the battery, connect it to the appropriate charger and allow it to charge until it reaches its full capacity. Most chargers have indicators (usually an LED light) that signal when the battery is fully charged. It is advisable to leave the battery connected for a few minutes after the indicator shows full charge to ensure it is completely topped off. This step is essential because even a slight undercharge can lead to erroneous capacity measurements.

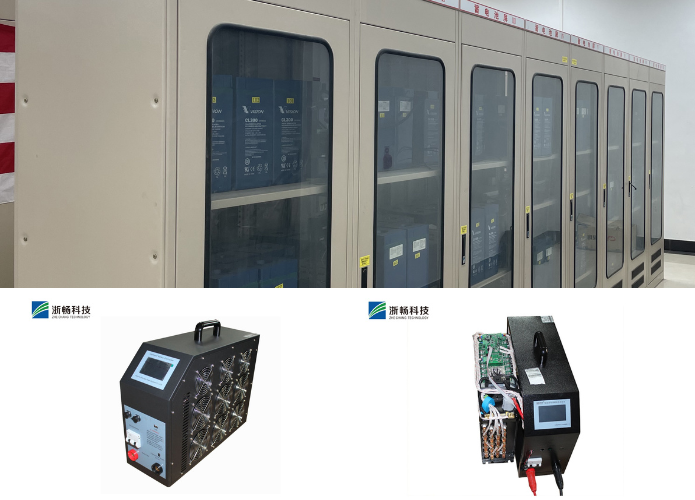

Step 2: Set Up the Lithium Battery Capacity Tester

Once the battery is fully charged, the next step is to set up the lithium battery capacity tester. This device is designed to measure the amount of charge that the battery can deliver by discharging it at a controlled rate.

Connecting the Battery to the Tester

The battery capacity tester typically comes with two terminals: one for the positive end and one for the negative end of the battery. Carefully connect the positive terminal of the battery to the positive terminal of the tester, and the negative terminal of the battery to the negative terminal of the tester. It is essential to ensure that these connections are secure and correct, as improper connections can lead to inaccurate measurements or even damage the battery or tester.

Configuring the Tester

Some advanced battery testers allow you to configure the discharge parameters, such as the discharge current and cutoff voltage. The discharge current is the rate at which the tester draws power from the battery, while the cutoff voltage is the minimum voltage level at which the tester will stop discharging the battery to prevent over-discharge. Setting the correct parameters is important because they can affect the accuracy of the capacity measurement.

Step 3: Begin the Discharge Process

With the battery securely connected to the tester and the parameters set, you can now begin the discharge process.

Understanding the Discharge Process

The capacity tester works by drawing a constant current from the battery, simulating a real-world load. As the battery discharges, the tester measures the amount of energy (in mAh or Ah) that is delivered until the battery reaches its cutoff voltage. The constant current discharge is crucial because it provides a standardized way of measuring capacity, making it easier to compare the results with the battery's rated capacity.

Duration of the Discharge Process

The length of the discharge process depends on the capacity of the battery and the discharge current. For instance, a 3000mAh battery discharged at 1A (1000mA) will take approximately 3 hours to fully discharge. During this time, the tester will continuously monitor and record the voltage, current, and energy delivered by the battery.

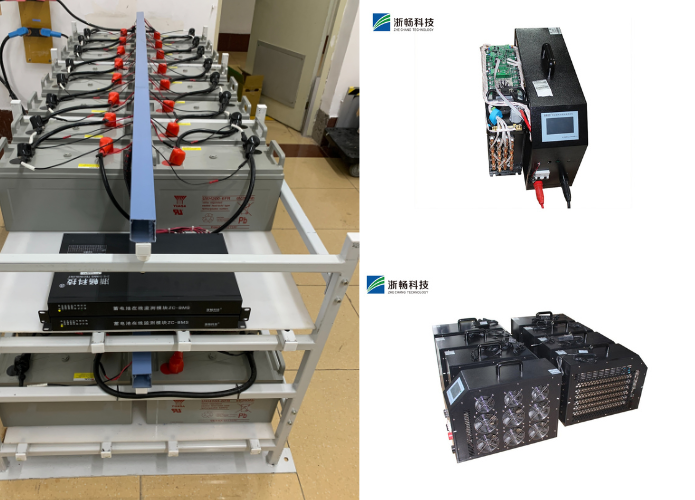

Step 4: Monitor the Test

While the battery is discharging, it is important to monitor the test to ensure that everything is running smoothly.

Real-Time Monitoring

Most modern lithium battery capacity testers come with a digital display that provides real-time data on the battery's voltage, discharge current, and the capacity being measured. Monitoring this data allows you to ensure that the discharge process is proceeding as expected and that there are no issues such as unexpected voltage drops or fluctuations in the discharge current.

Safety Considerations

During the discharge process, it is important to monitor the temperature of the battery, especially if you are testing high-capacity batteries or discharging at a high current. Lithium batteries can become hot during discharge, and excessive heat can indicate a problem with the battery or the tester. If the battery becomes too hot, it is advisable to stop the test and allow the battery to cool down before continuing.

Step 5: Record the Results

After the battery has been fully discharged, the capacity tester will display the total capacity of the battery.

Understanding the Results

The capacity is typically displayed in milliampere-hours (mAh) or ampere-hours (Ah), which represents the total amount of charge that the battery was able to deliver during the discharge process. This value is a direct measurement of the battery's true capacity at the time of the test.

Recording for Future Reference

It is important to record the capacity measurement for future reference. Keeping a log of your battery's capacity over time can help you track its health and performance, allowing you to identify when the battery is beginning to degrade.

Step 6: Compare the Results to the Rated Capacity

The final step in the process is to compare the measured capacity with the rated capacity provided by the battery manufacturer.

Analyzing the Comparison

The rated capacity is the manufacturer's specified capacity for the battery when it is new and in optimal condition. If the measured capacity is close to the rated capacity, it indicates that the battery is still in good condition. However, if the measured capacity is significantly lower than the rated capacity, it may be a sign that the battery is aging or has degraded.

Decision Making Based on Results

If the capacity has decreased substantially, you may need to consider replacing the battery, especially if it is no longer providing sufficient runtime for your application. A reduction in capacity can also indicate other issues, such as internal resistance build-up, which can further affect the battery's performance.

Manual Method for Testing Lithium Battery Capacity

If you don't have a lithium battery capacity tester, you can still test your battery's capacity manually using a multimeter and a load resistor. Here's how:

Fully Charge the Battery

As with the previous method, start by fully charging the battery.

Connect the Multimeter and Load Resistor

Connect the multimeter in series with the battery and the load resistor. Set the multimeter to measure current (in amps). The load resistor should be chosen based on the battery's voltage and the desired discharge current. For example, if you want to discharge at 1 amp and your battery is 3.7V, you would use a 3.7-ohm resistor.

Begin the Discharge

Allow the battery to discharge through the resistor. Use the multimeter to monitor the current continuously.

Measure the Voltage Over Time

Periodically measure the voltage across the battery terminals. Continue this process until the battery voltage drops to its cutoff level (typically around 3.0V for lithium-ion batteries).

Calculate the Capacity

To calculate the capacity, use the formula:

Capacity (mAh) = (Current (A) × Time (hours))

Multiply the current by the time it took for the battery to discharge to the cutoff voltage. This will give you the capacity in mAh.

Compare the Results

Compare the calculated capacity to the manufacturer's rated capacity to assess the battery's condition.

Factors That Affect Lithium Battery Capacity Testing

Several factors can influence the accuracy of your lithium battery capacity tests. Being aware of these can help you achieve more reliable results:

Temperature

Temperature has a significant impact on lithium battery performance. Testing at too high or too low a temperature can yield inaccurate results. For best results, test your battery at room temperature (around 20-25°C).

Discharge Rate

The rate at which you discharge the battery (current draw) affects the measured capacity. A higher discharge rate usually results in a lower capacity reading because the battery's efficiency decreases under heavier loads. It's important to test the battery under conditions that closely match its intended use.

Battery Age

As lithium batteries age, their capacity naturally declines. Even if the battery has been properly maintained, you can expect a decrease in capacity over time.

State of Charge

Starting the test with a battery that is not fully charged can lead to inaccurate results. Always ensure the battery is at 100% charge before testing.

Best Practices for Testing Lithium Battery Capacity

To get the most accurate and reliable results from your lithium battery capacity tests, follow these best practices:

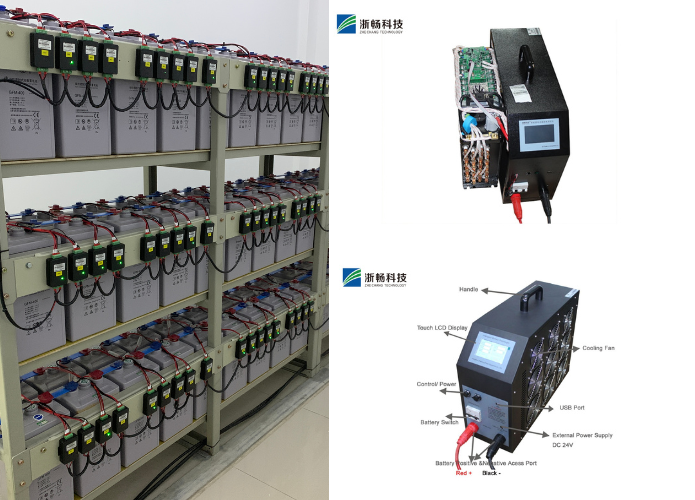

Use a Reliable Lithium Battery Capacity Tester

Invest in a high-quality lithium battery capacity tester. Cheap or poorly made testers may not provide accurate readings and could even damage your battery.

Test Regularly

Make it a habit to test your batteries regularly, especially if they are used in critical applications like medical devices or electric vehicles. This will help you catch any decline in performance early.

Maintain Proper Records

Keep a log of your battery tests, including the date, measured capacity, and any other relevant data. This will help you track the battery's performance over time and identify any trends or issues.

Store Batteries Properly

Proper storage of lithium batteries can prolong their life and maintain their capacity. Store batteries in a cool, dry place and avoid letting them discharge completely.

Replace When Necessary

If a battery's capacity drops significantly, it may be time to replace it. Continuing to use a degraded battery can lead to reduced performance and potential safety risks.

Understanding the Limitations of Lithium Battery Capacity Testing

While testing the capacity of a lithium battery is essential for maintaining its performance, it's important to understand that no test is perfect. Various factors, including the battery's age, usage history, and testing conditions, can affect the results. Additionally, the capacity measured in a test may differ slightly from the battery's real-world performance due to variations in how the battery is used.

Real-World Usage vs. Test Conditions

In real-world usage, batteries are often subjected to fluctuating loads, temperatures, and discharge rates. These conditions can differ significantly from the controlled environment of a capacity test, leading to different performance outcomes.

Accuracy of Testing Equipment

Even the most sophisticated lithium battery capacity tester has a margin of error. While these devices are generally reliable, it's essential to consider the potential for minor inaccuracies in the results.

Conclusion

Testing the capacity of lithium batteries is a critical aspect of maintaining their performance and ensuring safety. Whether you use a dedicated lithium battery capacity tester or a manual method, understanding the steps involved and the factors that influence the results will help you achieve accurate measurements.

Regular testing, proper storage, and timely replacement of batteries are key practices that can extend the life of your lithium batteries and keep them functioning at their best. By following the guidelines outlined in this article, you can confidently test your lithium battery capacity and make informed decisions about their use.

Popular Battery Tester

Popular Battery Tester

Latest News

Latest News

Get Price of Battery Tester

Get Price of Battery Tester

Address:

Floor 3, Building 1, No.1418-60, Moganshan road, Hangzhou city, Zhejiang Province, China.310015