High Voltage vs. Low Voltage Battery Management Systems: A Comprehensive Comparison

Battery Management Systems (BMS) are integral to the safe and efficient operation of battery-powered applications. Whether you're driving an electric vehicle (EV), installing an energy storage system (ESS) for solar energy, or managing smaller consumer electronics, a BMS ensures the battery operates optimally, safely, and efficiently. The core function of a BMS is to oversee the health, safety, and performance of the battery by monitoring parameters like charge levels, temperature, and voltage, while also providing protection mechanisms to prevent damage.

However, the design of the BMS can vary significantly depending on the voltage range of the battery it manages. Two primary categories of BMS exist: high voltage battery management systems and low voltage battery management systems. While both serve the same essential purpose, they are designed for different use cases and have distinct features and characteristics. In this comprehensive comparison, we will explore the differences between high voltage and low voltage BMS, including their applications, advantages, challenges, and key features.

What is a Battery Management System (BMS)?

A Battery Management System (BMS) is a sophisticated electronic system designed to monitor and control the charging and discharging of a battery pack. It ensures that the battery operates within safe operating conditions, preventing risks such as overcharging, deep discharging, thermal runaway, or battery failure. The primary functions of a BMS include:

- Battery Monitoring: The BMS continuously monitors the battery's state of charge (SOC), state of health (SOH), and temperature. By doing so, it provides real-time data on the battery's performance and helps predict its lifespan.

- Protection: The system ensures the battery is protected from conditions that could damage it, such as excessive voltage (overvoltage), insufficient voltage (undervoltage), high temperatures, and overcurrent conditions.

- Balancing: In multi-cell batteries, the BMS ensures that all cells are balanced, meaning they all maintain a similar voltage level. This is crucial to ensure that no single cell is overcharged or over-discharged, as this can lead to reduced battery life or failure.

- Communication: The BMS communicates with other systems—such as the vehicle control unit in an EV or the energy management system in a solar-powered home—to report data on battery performance and health.

With that foundational understanding of BMS, let's explore how high voltage and low voltage systems differ and what makes each of them suitable for specific applications.

High Voltage Battery Management System

Overview

A high voltage battery management system is designed for managing batteries that operate at higher voltage levels—typically greater than 60V and often reaching several hundred volts. These systems are essential for applications requiring significant energy capacity and high power output. High voltage BMS is used in industries such as electric vehicles (EVs), renewable energy storage systems, industrial machinery, and high-power applications. In these use cases, battery packs are designed to provide large amounts of power and energy over extended periods.

Key Features of High Voltage BMS

1.Higher Voltage Rating: High voltage battery packs typically range from 100V to 800V, and in some specialized cases, they can go higher. This higher voltage allows the battery to store more energy, which is essential for powering larger devices like EVs, heavy machinery, and large-scale energy storage systems. The BMS is designed to safely manage these higher voltages, ensuring that each cell in the pack operates within safe voltage limits.

2.Cell Configuration: High voltage battery systems consist of many cells connected in series (to increase voltage) and parallel (to increase capacity). The BMS must handle a large number of cells, continuously balancing them to ensure that no cell is overcharged or discharged more than the others. This is critical for both performance and longevity, as imbalanced cells can result in lower capacity or even failure.

3.Advanced Thermal Management: High voltage battery packs tend to generate significant heat during both charging and discharging. Excess heat can damage the battery cells and cause safety issues. Therefore, high voltage BMSs incorporate advanced thermal management systems, which include active or passive cooling mechanisms to maintain optimal operating temperatures. This can involve the use of liquid cooling, heat sinks, or fans to ensure heat dissipation.

4.Protection Mechanisms: Given the increased energy and power capacity of high voltage systems, the BMS must include robust protection mechanisms. These include:

- Overvoltage Protection: Prevents the battery from being charged beyond a certain voltage, which can cause overheating, fires, or battery degradation.

- Undervoltage Protection: Prevents excessive discharge, which can damage cells or result in battery failure.

- Overcurrent Protection: Safeguards the battery from excessive current flow, which can cause thermal runaway.

- Isolation Fault Detection: High voltage systems include insulation monitoring to detect and isolate faults within the system.

Applications of High Voltage BMS

High voltage battery management systems are used in a variety of applications where large-scale energy storage and high power output are required, including:

- Electric Vehicles (EVs): In EVs, high voltage battery packs are essential for providing the power needed to drive electric motors over long distances. Battery packs in electric cars, buses, trucks, and motorcycles typically range from 400V to 800V. The BMS ensures the vehicle operates efficiently and safely by monitoring battery performance, balancing cells, and managing power distribution to the motor and other components.

- Energy Storage Systems (ESS): High voltage battery packs are used to store energy generated by renewable sources like solar panels or wind turbines. These systems help to stabilize the grid by storing excess energy during periods of high generation and releasing it when demand is high. High voltage BMS ensures that the battery operates at optimal performance levels for extended periods.

- Industrial Applications: In sectors such as mining, material handling, and construction, high voltage batteries are used in equipment like electric forklifts, mining trucks, and electric cranes. These systems require large amounts of power to operate heavy machinery, and the BMS ensures the batteries provide reliable energy over long shifts.

Advantages of High Voltage BMS

- Higher Power Output: High voltage systems are capable of supplying significant power and are ideal for demanding applications such as EVs and industrial equipment. They can handle high currents more efficiently, as higher voltage allows for lower current draw for the same power output.

- Energy Efficiency: High voltage systems tend to be more energy-efficient when it comes to large-scale applications. The lower current reduces resistive losses in the cables, connectors, and other components, leading to better efficiency and less heat generation.

- Scalability: High voltage systems can be scaled to meet the growing power demands of large systems. Whether it’s an EV battery pack or a renewable energy storage system, high voltage BMSs allow for easy scalability by adding more cells or modules.

Challenges of High Voltage BMS

- Safety Risks: The higher the voltage, the greater the potential safety risks. High voltage battery systems pose significant electrocution, fire, and thermal runaway risks if not managed correctly. BMSs in high voltage applications must employ rigorous safety measures, including insulation, fault detection, and emergency disconnect mechanisms.

- Cost and Complexity: Due to the complexity of managing high voltages, high voltage BMS systems are more expensive to design, implement, and maintain. Additionally, the need for more advanced components and safety protocols makes them costlier than low voltage alternatives.

- Cooling Requirements: High voltage systems generate more heat and require advanced thermal management solutions, which can add to the system’s overall cost and complexity.

Low Voltage Battery Management System

Overview

A low voltage battery management system is designed to manage battery packs that operate at lower voltage levels, typically ranging from 3.6V to 60V. Low voltage systems are widely used in applications such as consumer electronics, electric bicycles, portable devices, and low-power electric vehicles. These systems are generally simpler, more cost-effective, and are used for managing smaller batteries with less demanding energy output requirements.

Key Features of Low Voltage BMS

- Lower Voltage Rating: Low voltage systems typically manage battery packs with voltages in the 3.6V to 60V range. The lower voltage requirements make them ideal for small-scale applications, such as consumer electronics, e-bikes, and small power tools.

- Simple Architecture: Low voltage battery packs are usually composed of fewer cells connected in series and parallel to achieve the desired voltage and capacity. Because of the simpler architecture, the BMS is less complex and easier to design compared to high voltage systems.

- Basic Protection Features: While low voltage BMS still includes essential protections (overcharge, undercharge, and short-circuit protection), these systems generally don't require the extensive protection mechanisms that high voltage systems do. The risk of thermal runaway or catastrophic failure is lower, but still important to address.

- Energy Efficiency: Low voltage systems are optimized for low-power applications, which means they are generally more energy-efficient in terms of both power consumption and cost. The efficiency is suitable for the smaller power requirements of devices like smartphones, drones, or power tools.

- Cost-Effective: Low voltage systems are generally cheaper to produce and implement than high voltage systems. The simplicity of their design leads to lower manufacturing costs, making them ideal for mass-produced consumer goods.

Applications of Low Voltage BMS

Low voltage BMSs are used in a variety of everyday applications, such as:

- Consumer Electronics: Smartphones, laptops, tablets, and other portable devices rely on low voltage lithium-ion batteries. The BMS in these devices ensures that the battery is charged properly and operates safely without risk of overheating, overcharging, or short-circuiting.

- Electric Bicycles and Scooters: Low voltage BMSs are used in e-bikes and electric scooters, typically with battery packs in the 36V to 48V range. The BMS ensures the battery is charged safely and efficiently, protecting against overcharging and ensuring the battery’s longevity.

- Portable Power Tools: Many power tools, such as drills, saws, and lawnmowers, use low voltage batteries (usually 12V to 24V). The BMS ensures that these tools can be used safely and effectively for extended periods.

Advantages of Low Voltage BMS

- Cost-Effective: As mentioned, low voltage BMSs are generally more affordable due to their simpler design and fewer components.

- Safety: Low voltage systems generally have lower safety risks than high voltage systems. Although safety features are still important, they don’t require the same degree of complexity or high-end protection mechanisms.

- Simplicity and Ease of Use: Low voltage systems are easier to install, maintain, and troubleshoot compared to high voltage systems, making them suitable for consumer-grade devices and applications.

Challenges of Low Voltage BMS

- Limited Power Output: Low voltage systems are limited in terms of the amount of power they can deliver. They are typically suitable for low-power applications but may struggle to meet the needs of high-power systems like electric vehicles or large energy storage installations.

- Battery Life: While low voltage systems are energy-efficient, they typically do not offer the same range or performance as high voltage systems. This can be a limiting factor in applications requiring high continuous output or long operational times.

Conclusion

Both high voltage and low voltage battery management systems are essential for different types of applications, and the choice between the two depends on the specific needs of the system or device you are designing. If you need to power high-performance applications that require significant energy and power output—such as electric vehicles, industrial machines, or energy storage systems—a high voltage BMS is the way to go. On the other hand, for more compact, cost-effective, and energy-efficient applications like consumer electronics, e-bikes, and power tools, a low voltage BMS is ideal.

Ultimately, the right BMS ensures the battery operates safely, efficiently, and for as long as possible, helping optimize energy usage and improve the overall performance of modern battery-powered devices.

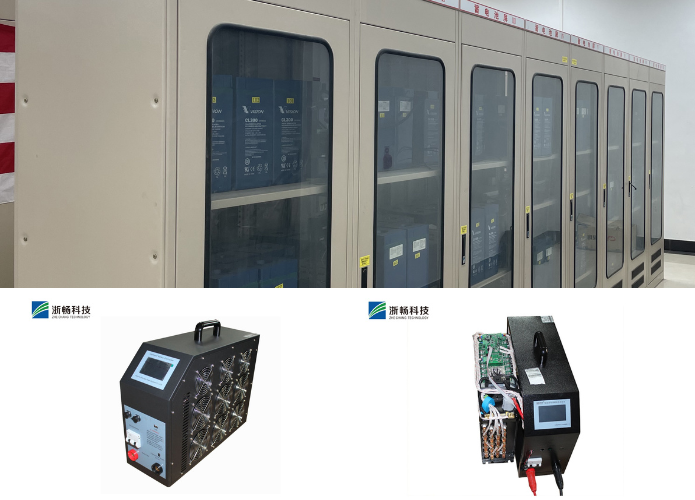

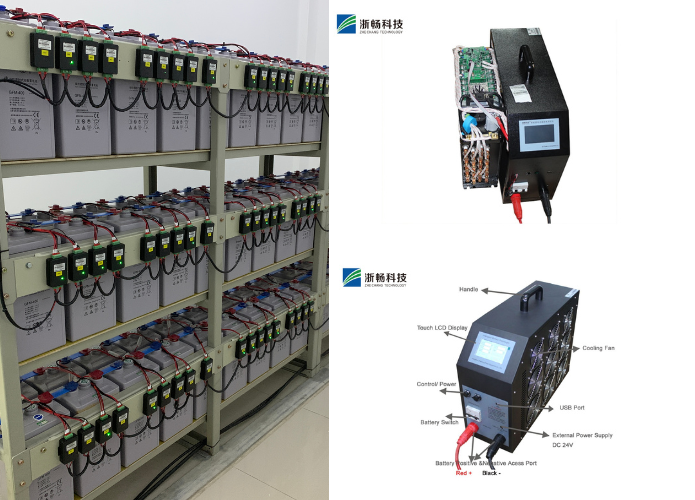

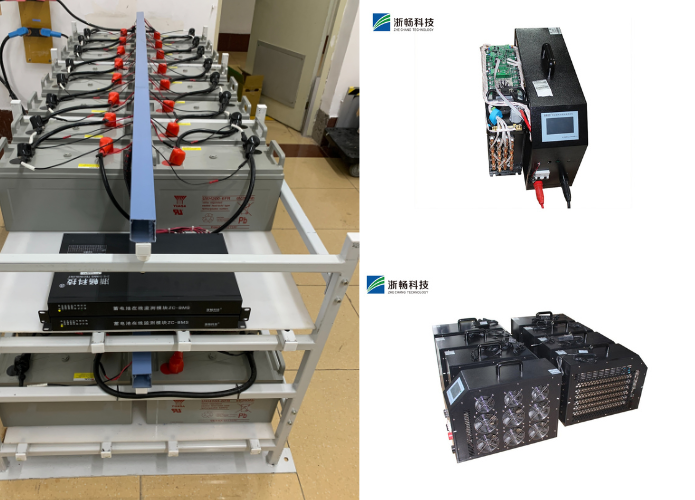

Popular Battery Tester

Popular Battery Tester

Latest News

Latest News

Get Price of Battery Tester

Get Price of Battery Tester

Address:

Floor 3, Building 1, No.1418-60, Moganshan road, Hangzhou city, Zhejiang Province, China.310015