How Do You Measure Battery Capacity?

Battery capacity is a critical parameter that defines the energy a battery can store and deliver. Whether you're dealing with small batteries for portable devices or large batteries for electric vehicles, understanding how to measure battery capacity is essential for optimizing performance, ensuring safety, and extending battery life. How Do You Measure Battery Capacity? This guide explores the methods, tools, and best practices for measuring battery capacity, focusing on key devices like battery capacity discharge testers and battery capacity checkers.

What is Battery Capacity?

Battery capacity refers to the total amount of energy a battery can hold and deliver under specified conditions. It is influenced by several factors, including the battery's chemistry, age, temperature, and discharge rate. Battery capacity is a fundamental indicator of a battery's performance, directly impacting the runtime of electronic devices.

Battery capacity is the amount of electrical energy a battery can store, typically measured in milliampere-hours (mAh) or ampere-hours (Ah). This capacity determines how long a battery can power a device before needing a recharge. Understanding battery capacity is crucial for selecting the right battery for your application and for maintaining its performance over time.

Importance of Measuring Battery Capacity

Measuring battery capacity is vital for several reasons:

- Performance Assessment: It helps in evaluating whether a battery is capable of meeting the energy demands of a specific application.

- Maintenance: Regular capacity checks can identify aging or failing batteries before they cause problems.

- Safety: Accurate measurement prevents overloading or deep discharging, which can damage the battery or even cause safety hazards.

- Optimization: By understanding capacity, you can optimize charging cycles and extend battery life.

What is Battery Capacity Measurement?

Battery capacity measurement is not just about reading a number off a device; it involves understanding the principles behind the measurements, the tools used, and the conditions under which they are taken.

Key Terms in Battery Capacity Measurement

- Voltage (V): The electrical potential difference between two points. For batteries, it is a critical factor in determining how much energy is being delivered.

- Current (A): The flow of electric charge, measured in amperes. It directly impacts how quickly a battery discharges.

- C-rate: The rate at which a battery is discharged relative to its maximum capacity. A 1C rate means discharging the battery in one hour.

- State of Charge (SoC): The current charge level of a battery as a percentage of its total capacity.

- Depth of Discharge (DoD): The percentage of battery capacity that has been used. A higher DoD can lead to faster battery degradation.

Factors Affecting Battery Capacity

Several factors can influence the measured capacity of a battery:

- Temperature: Batteries typically perform best at moderate temperatures. Extreme cold or heat can significantly reduce capacity.

- Discharge Rate: Higher discharge rates usually reduce the apparent capacity because the battery has less time to deliver its stored energy.

- Battery Age: Over time, all batteries degrade, leading to a reduction in their capacity.

- Battery Chemistry: Different types of batteries (e.g., lithium-ion, nickel-metal hydride) have different capacities and behaviors under various conditions.

How Do You Measure Battery Capacity?

There are several methods to measure battery capacity, each with its own advantages and specific applications. The choice of method depends on factors such as the type of battery, the required level of accuracy, and the available equipment.

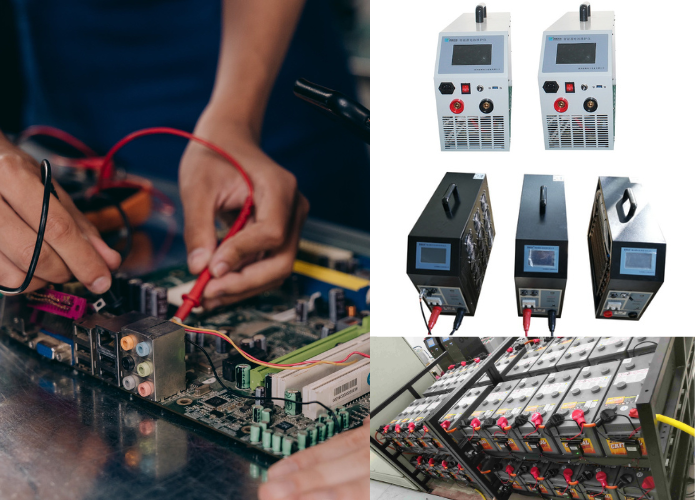

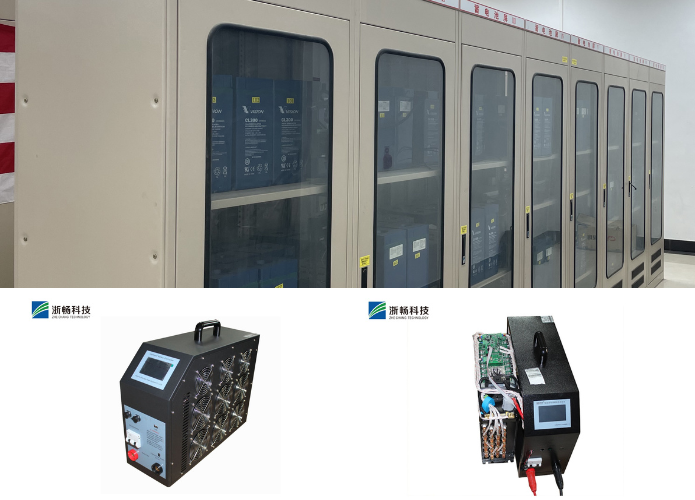

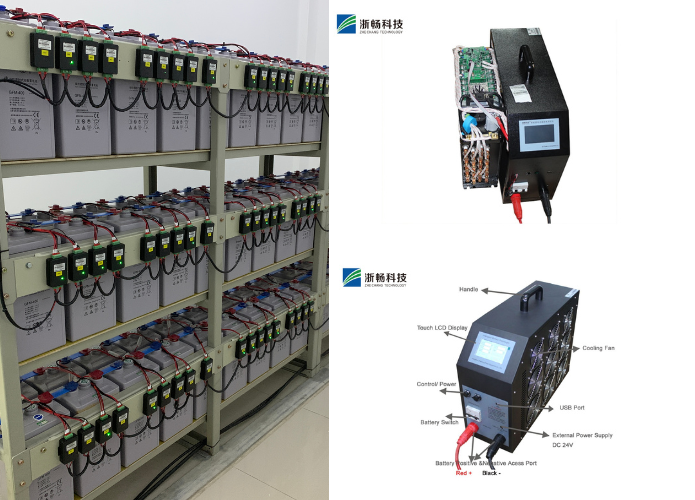

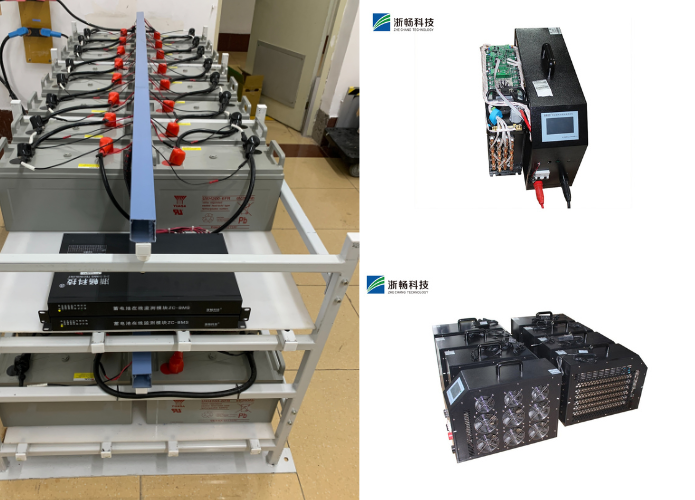

One common approach is direct measurement using a battery capacity discharge tester. This device is specifically designed to assess battery capacity by discharging the battery at a controlled rate and measuring the total energy delivered until the battery is fully discharged.

In terms of operation, a battery capacity discharge tester works by applying a consistent load to the battery and measuring the time it takes for the battery to reach its cutoff voltage, which is the point at which the battery is considered fully discharged.

There are several advantages to using a discharge tester. First, it provides a highly accurate measurement of the battery's capacity. Second, it simulates real-world conditions by discharging the battery under a controlled load, which can reflect how the battery will perform in practical use. Additionally, many discharge testers offer data logging capabilities, allowing for detailed analysis of the battery's performance over time.

Among popular battery capacity discharge testers, the West Mountain Radio CBA IV is known for its precision and versatility, making it suitable for testing a wide range of battery types. Another option is the ZKE EBD-A20H, a more affordable alternative that provides reliable results for smaller batteries.

Another method for evaluating battery capacity is through the use of a battery capacity checker. This simpler tool provides a quick estimate of a battery’s remaining capacity, often used for routine checks. Battery capacity checkers are particularly popular in applications like remote-controlled vehicles and drones due to their ease of use and practicality.

Using a Battery Capacity Checker Measure Battery Capacity

Battery capacity checkers typically function by measuring the battery's voltage and estimating its remaining capacity based on predefined curves tailored to different battery chemistries. Some advanced models take this a step further by also measuring the battery's internal resistance, providing a more accurate estimate of the remaining capacity.

There are several advantages to using a battery capacity checker. One key benefit is its convenience; these devices are portable and easy to use, making them ideal for quick checks in the field. They are also cost-effective, generally being more affordable than battery discharge testers. Additionally, capacity checkers are versatile and can be used with a variety of battery types and chemistries.

Some popular battery capacity checkers include the ISDT BG-8S, which is known for its accuracy and support for multiple battery types, including LiPo, Li-ion, and NiMH. Another option is the Hobbymate D6 Duo Pro, which offers dual-channel testing and a clear display for easy readability.

Best Practices for Accurate Battery Capacity Measurement

Accurate battery capacity measurement is essential for evaluating a battery's performance and ensuring it meets the requirements of its intended application. To achieve reliable results, it's important to follow best practices during the measurement process. These practices help minimize errors and provide a clear understanding of the battery’s actual capabilities under various conditions.

One key best practice is to ensure that the battery is fully charged before performing any capacity measurements. A fully charged battery provides a consistent baseline for testing and ensures that the entire discharge cycle can be measured. Incomplete charging can lead to inaccurate capacity readings, as the test will not reflect the battery's full potential. Using a high-quality charger that matches the battery's specifications is also crucial for ensuring proper charging.

Another important factor is using an appropriate load for the discharge test. The load applied to the battery during the test should reflect the typical usage conditions the battery will encounter in real-world applications. Using a load that is too high or too low can skew the results, leading to an inaccurate measurement of the battery's actual capacity. Load conditions should also be consistent throughout the test to maintain accuracy.

Temperature control is another critical element in accurate battery capacity measurement. Batteries are sensitive to temperature, and their performance can vary significantly in different thermal environments. Testing batteries at a stable, recommended temperature (usually room temperature) ensures more reliable and repeatable results. If the battery operates in extreme temperatures, tests should be conducted under those specific conditions to understand its performance in that environment.

Lastly, for batteries that will be tested multiple times, it is essential to track the battery's internal resistance. Over time, a battery's internal resistance increases due to age and use, which can impact its capacity. Regularly monitoring this metric can help predict when a battery may be nearing the end of its usable life and provide more context to capacity measurements.

Applications of Battery Capacity Measurement

Understanding and measuring battery capacity is critical across various industries and applications.

1. Consumer Electronics

Battery capacity is a key factor in the design and performance of consumer electronics, from smartphones to laptops. Accurate measurement ensures that these devices deliver the promised battery life and performance.

Smartphones and Tablets: Manufacturers use capacity measurements to optimize battery life and performance, balancing size, weight, and power.

Laptops: Battery capacity directly influences runtime, a critical selling point in the competitive market for portable computing devices.

2. Electric Vehicles (EVs)

In electric vehicles, battery capacity determines range, performance, and overall efficiency. Regular capacity checks are crucial for maintaining the health and safety of EV batteries.

Range Anxiety: Accurate capacity measurements help mitigate range anxiety by providing precise estimates of how far an EV can travel on a single charge.

https://www.zcbatterytester.com/pages/battery-management-system

Battery Management Systems (BMS): Advanced BMS use real-time capacity monitoring to optimize charging, discharging, and thermal management.

3. Renewable Energy Storage

In renewable energy systems, such as solar or wind, batteries store energy for use when generation is low. Capacity measurements ensure these systems can reliably meet energy demands.

Off-Grid Systems: In off-grid solar power systems, knowing battery capacity is critical for ensuring energy availability during periods of low sunlight.

Grid-Tied Systems: For grid-tied systems with battery backup, accurate capacity measurement helps optimize the integration of renewable energy into the grid.

4. Industrial and Commercial Applications

Battery capacity measurement is also vital in industrial and commercial settings, where reliable power is crucial.

Uninterruptible Power Supplies (UPS): In data centers and critical infrastructure, battery capacity checks ensure that backup power is available when needed.

Power Tools: For cordless power tools, battery capacity directly impacts performance and user productivity.

Advances in Battery Capacity Measurement Technology

As battery technology evolves, so do the methods for measuring battery capacity. New tools and techniques are being developed to provide more accurate, efficient, and user-friendly capacity measurements.

1. Smart Battery Monitors

Smart battery monitors integrate capacity measurement with advanced features like real-time monitoring, predictive analytics, and wireless connectivity.

Real-Time Data: These monitors provide continuous, real-time data on battery capacity, state of charge, and health.

Predictive Maintenance: By analyzing capacity trends, smart monitors can predict when a battery is likely to fail, allowing for proactive maintenance.

2. Advanced Battery Management Systems (BMS)

Modern BMS in electric vehicles and renewable energy systems are incorporating more sophisticated capacity measurement techniques, including machine learning and AI.

Adaptive Algorithms: These systems can adapt to changing conditions, improving the accuracy of capacity measurements over time.

Integrated Diagnostics: Advanced BMS can diagnose capacity loss and other issues, providing insights into battery health and longevity.

3. High-Precision Instruments

New high-precision instruments are being developed to measure battery capacity with greater accuracy and under a wider range of conditions.

Precision Coulomb Counters: These devices offer enhanced accuracy for applications where even small errors in capacity measurement can have significant consequences.

Temperature-Compensated Testers: Instruments that automatically compensate for temperature variations provide more reliable capacity measurements in fluctuating environments.

Challenges in Battery Capacity Measurement

While there have been significant advances, measuring battery capacity still presents several challenges.

1. Variability in Battery Chemistry

Different battery chemistries have different characteristics, making it difficult to apply a one-size-fits-all approach to capacity measurement.

Lithium-Ion: Known for high energy density but sensitive to temperature and discharge rates.

Nickel-Metal Hydride (NiMH): More tolerant of abuse but with a lower energy density than lithium-ion batteries.

2. Measurement Accuracy

Achieving high accuracy in capacity measurement can be difficult, especially in dynamic environments.

Environmental Factors: Temperature, humidity, and pressure can all affect measurement accuracy.

Instrument Calibration: Ensuring instruments are properly calibrated is crucial but can be challenging in field conditions.

3. Battery Degradation

Over time, all batteries degrade, leading to a gradual loss of capacity. Measuring this degradation accurately is essential for predicting battery life but is complicated by the non-linear nature of the degradation process.

Conclusion

Measuring battery capacity is a crucial aspect of battery management across various industries and applications. Whether you're using a battery capacity discharge tester for precise measurements or a battery capacity checker for quick assessments, understanding the capacity of your batteries ensures they meet performance expectations, last longer, and operate safely. As technology continues to evolve, new tools and methods are making it easier to measure and monitor battery capacity accurately, helping to optimize battery usage and extend their lifespan.

Popular Battery Tester

Popular Battery Tester

Latest News

Latest News

Get Price of Battery Tester

Get Price of Battery Tester

Address:

Floor 3, Building 1, No.1418-60, Moganshan road, Hangzhou city, Zhejiang Province, China.310015