Innovative Technologies and Trends in the Battery Testing Industry in 2025

Introduction to the Evolving Battery Testing Industry

The battery testing industry is undergoing a profound transformation as energy storage technologies advance. Driven by the increasing adoption of electric vehicles (EVs), renewable energy integration, and portable electronics, the demand for high-performance batteries has surged. This shift necessitates rigorous testing methodologies to ensure battery reliability, safety, and efficiency.

In 2025, battery testing technologies are evolving to meet new challenges posed by emerging battery chemistries, high-capacity storage solutions, and the need for sustainability. With governments enforcing stricter regulations on battery safety and performance, industries must adopt state-of-the-art testing protocols. This article explores the cutting-edge innovations that are shaping the battery testing landscape and their implications for the future.

Advanced Battery Chemistry Testing

As new battery chemistries such as solid-state, lithium-sulfur, and sodium-ion batteries gain traction, conventional testing methods are no longer sufficient. Each chemistry presents unique characteristics that require specialized testing protocols.

- Solid-state batteries: These offer improved energy density and safety but require testing for ionic conductivity, electrode-electrolyte interfaces, and degradation mechanisms.

- Lithium-sulfur batteries: Known for their high energy density, these batteries must be tested for cycle stability and sulfur cathode degradation.

- Sodium-ion batteries: A promising alternative to lithium-ion, sodium-ion batteries require evaluation of their electrochemical performance, temperature resilience, and long-term durability.

Advancements in spectroscopy, electrochemical impedance analysis, and AI-driven simulations are enhancing the accuracy and efficiency of battery chemistry testing.

AI-Driven Battery Testing and Predictive Analytics

Artificial intelligence (AI) and machine learning (ML) are revolutionizing battery testing by enabling predictive analytics. AI-driven algorithms analyze massive datasets from battery tests to detect patterns, identify potential failures, and optimize performance.

- Failure prediction: AI can assess charge-discharge cycles to detect early signs of battery degradation.

- Optimization of testing protocols: AI helps streamline testing procedures by reducing redundant tests and focusing on critical parameters.

- Real-time health monitoring: AI-powered analytics allow continuous monitoring of battery performance in various applications, from EVs to grid storage.

By leveraging AI, manufacturers can enhance battery quality while reducing testing costs and time.

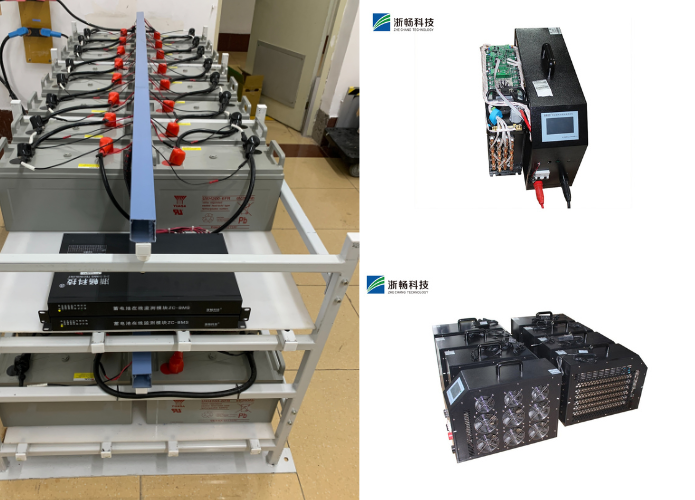

Smart Battery Testers with IoT Connectivity

The Internet of Things (IoT) is transforming battery testing by enabling real-time data transmission and remote diagnostics. Smart battery testers equipped with IoT connectivity allow seamless integration with cloud platforms, facilitating continuous monitoring and predictive maintenance.

- Remote monitoring: IoT-enabled testers transmit data to cloud servers, allowing engineers to track battery performance remotely.

- Automated alerts: In case of anomalies, these testers can send alerts to technicians, ensuring timely intervention.

- Data-driven decision-making: Real-time analytics improve battery manufacturing processes and enhance quality control.

IoT-based testing solutions improve efficiency, reduce downtime, and provide actionable insights for battery management.

High-Speed and Non-Invasive Testing Techniques

Traditional battery testing methods often involve invasive procedures that can compromise battery integrity. In 2025, high-speed and non-invasive techniques are emerging as game changers in the industry.

- X-ray and thermal imaging: These techniques provide real-time insights into battery cell structures and detect defects without disassembly.

- Electrochemical impedance spectroscopy (EIS): EIS allows quick assessment of battery health by analyzing impedance variations during charge and discharge cycles.

- Ultrasound diagnostics: By using ultrasonic waves, researchers can detect internal short circuits and mechanical deformations in batteries.

These advanced testing methods enhance accuracy while minimizing testing time and potential damage to batteries.

Battery Testing for Electric Vehicles (EVs)

The rapid expansion of the EV market has placed immense focus on battery testing tailored for automotive applications. EV batteries must meet stringent safety and performance standards to ensure longevity and user safety.

Key areas of EV battery testing include:

- Thermal management: Testing ensures that batteries maintain optimal temperature levels during operation.

- Cycle life assessment: EV batteries undergo thousands of charge-discharge cycles, requiring comprehensive durability testing.

- Crash and impact safety: Simulating real-world collision scenarios helps assess battery resilience under extreme conditions.

Collaboration between automakers and testing companies is crucial to developing standardized protocols that ensure battery safety and reliability in EV applications.

Enhanced Safety Testing Protocols

Battery safety is a top priority, especially with incidents of thermal runaway, fire hazards, and chemical leakage. In 2025, enhanced safety testing protocols are being implemented to prevent potential risks.

- Abuse testing: This involves subjecting batteries to extreme conditions, including overcharging, puncture, and high-temperature exposure.

- Early failure detection: Advanced sensors embedded in batteries help detect anomalies before they escalate into safety hazards.

- Standardized certification: Governments are enforcing stringent safety regulations to ensure compliance with international standards.

Enhanced safety testing ensures that batteries meet the highest safety benchmarks before reaching consumers.

Integration of Digital Twins in Battery Testing

Digital twin technology, which creates a virtual replica of a battery, is becoming a crucial tool in battery testing. These digital models allow engineers to simulate battery behavior under different conditions without physical testing.

- Accelerated R&D: Engineers can use digital twins to test new battery designs before physical prototypes are developed.

- Predictive maintenance: By analyzing real-time performance data, digital twins help predict when a battery may fail.

- Cost efficiency: Virtual simulations reduce the need for expensive and time-consuming physical tests.

The adoption of digital twins is streamlining battery development while enhancing performance optimization.

Sustainability and Eco-Friendly Testing Solutions

The battery industry is embracing sustainability by adopting eco-friendly testing methods that minimize waste and environmental impact.

- Recycling of tested batteries: New protocols focus on extracting valuable materials from discarded batteries.

- Energy-efficient testing: Low-energy testing equipment is reducing the carbon footprint of testing facilities.

- Sustainable materials: Battery manufacturers are shifting towards greener materials that improve recyclability.

By integrating sustainability into testing practices, companies are contributing to a greener energy ecosystem.

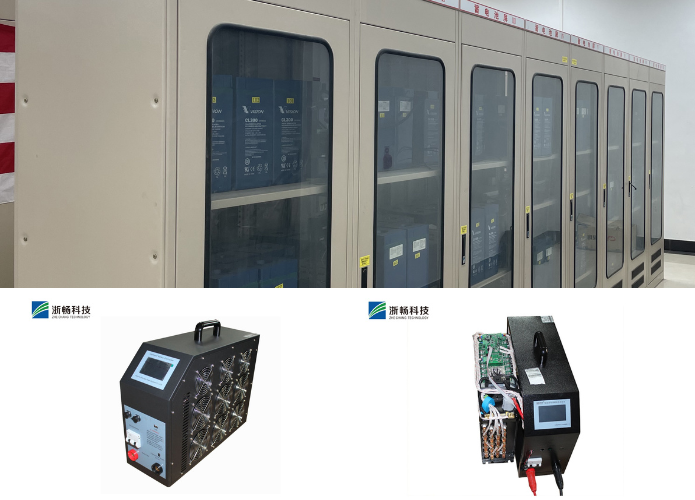

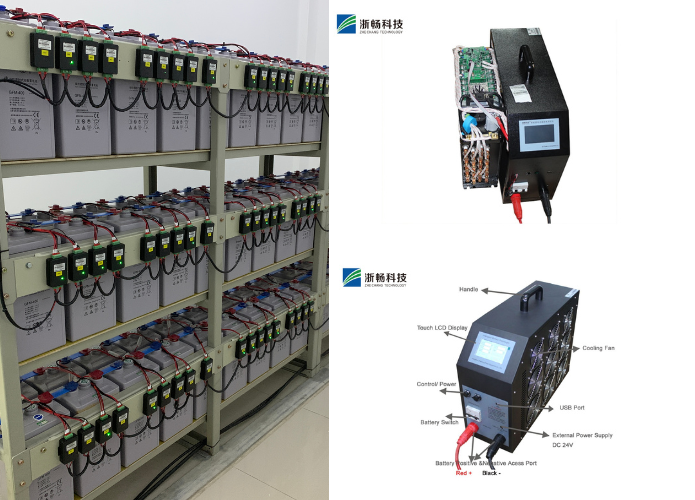

Modular and Scalable Battery Testing Platforms

Battery applications range from small consumer electronics to large-scale energy storage systems. To accommodate this diversity, modular and scalable testing platforms are being developed.

- Flexible configurations: These platforms can be customized for different battery types and sizes.

- Automated testing procedures: AI-powered automation enhances efficiency and reduces human error.

- Cost savings: Scalable testing solutions optimize resource utilization, making testing more economical.

These advancements provide manufacturers with adaptable solutions for a rapidly evolving battery landscape.

AI-Driven Battery Lifecycle Management

Beyond testing, AI is transforming battery lifecycle management by optimizing performance from production to end-of-life recycling.

- Real-time performance tracking: AI analyzes battery health in various applications, from EVs to smart grids.

- Predictive maintenance: AI-driven analytics help determine the best time for repairs or replacements.

- Recycling optimization: AI identifies the best recycling strategies to maximize resource recovery.

By integrating AI into lifecycle management, companies can enhance battery longevity and sustainability.

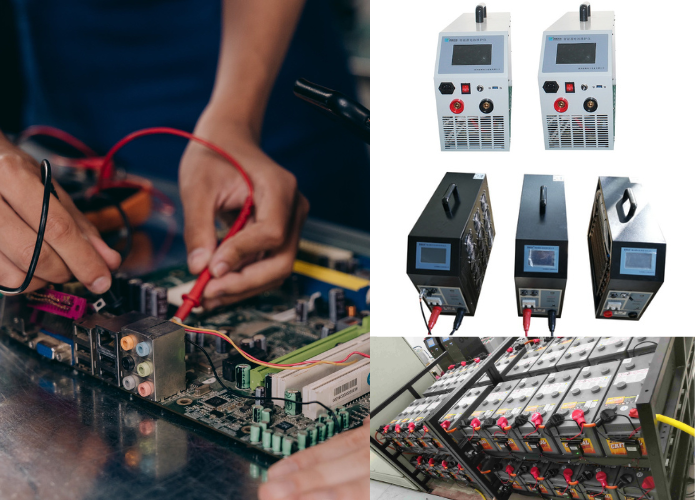

Collaboration Between Testing Equipment Manufacturers and Battery Producers

Collaboration between battery manufacturers and testing equipment developers is crucial for advancing testing methodologies.

- Joint R&D projects: Companies are working together to develop specialized testing protocols.

- Standardization efforts: Industry collaborations ensure uniform testing standards for different battery chemistries.

- Enhanced innovation: Partnerships accelerate the adoption of new technologies and improve battery performance.

Stronger collaboration is driving innovation and ensuring that testing technologies keep pace with evolving battery technologies.

Conclusion: The Future of Battery Testing in 2025 and Beyond

The battery testing industry in 2025 is defined by rapid technological advancements, AI-driven analytics, and sustainability-driven practices. Emerging trends such as digital twins, IoT-connected testers, and predictive AI analytics are revolutionizing how batteries are tested and managed.

As the demand for high-performance batteries continues to grow, the industry must embrace innovation and collaboration to meet future challenges. By integrating cutting-edge testing methodologies, companies can ensure that batteries are safer, more efficient, and environmentally sustainable for the years ahead.

Popular Battery Tester

Popular Battery Tester

Latest News

Latest News

Get Price of Battery Tester

Get Price of Battery Tester

Address:

Floor 3, Building 1, No.1418-60, Moganshan road, Hangzhou city, Zhejiang Province, China.310015