What is a Battery Charge Discharge Machine?

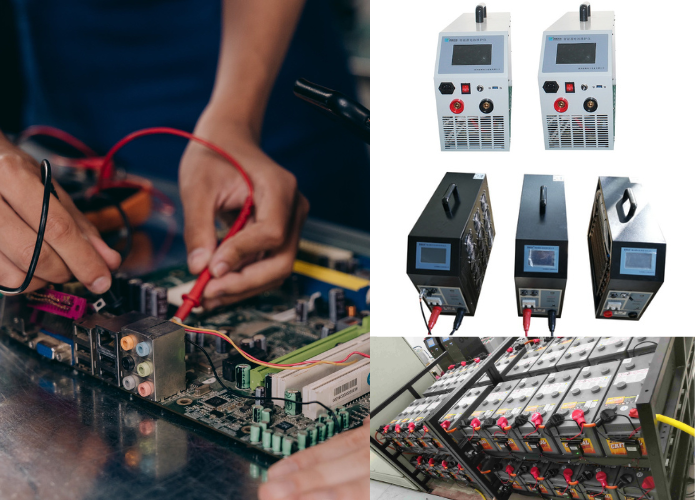

Battery Charge Discharge Machines (BCDM) are essential tools in the realm of battery technology. These machines are designed to charge and discharge batteries under controlled conditions, providing critical data that informs the development and optimization of battery systems. As the demand for efficient, high-capacity, and long-lasting batteries grows, particularly with the rise of electric vehicles and renewable energy storage, the role of BCDMs becomes increasingly significant. By simulating real-world operating conditions, BCDMs allow researchers and engineers to evaluate battery performance, understand degradation mechanisms, and enhance overall battery design.

What are Battery Charge Discharge Machines (BCDM)?

Battery Charge Discharge Machines are specialized devices used to test and evaluate the performance of batteries. These machines can precisely control the current and voltage applied to a battery, allowing for detailed analysis of its behavior during both charging and discharging cycles. The primary purposes of BCDMs include measuring battery capacity, cycle life, efficiency, and thermal characteristics. By providing accurate and repeatable data, BCDMs enable the identification of optimal operating conditions and the detection of potential issues such as capacity fade or thermal runaway. This information is crucial for developing safer, more reliable, and higher-performing batteries.

The evolution of Battery Charge Discharge Machines has paralleled advancements in battery technology. Early BCDMs were relatively simple, offering basic charge and discharge capabilities. However, as battery applications have expanded and performance requirements have become more stringent, BCDMs have evolved to include advanced features such as high-precision control, real-time data logging, and integrated safety mechanisms. Modern BCDMs can simulate a wide range of environmental conditions and usage scenarios, providing a comprehensive understanding of battery behavior.

The importance of BCDMs in battery technology research and development cannot be overstated. They play a critical role in the iterative process of battery innovation, enabling researchers to test new materials, designs, and chemistries. This testing is essential for ensuring that new batteries meet the stringent performance and safety standards required for commercial applications. Furthermore, the data obtained from BCDM testing is invaluable for modeling and simulation efforts, which help predict long-term battery performance and guide future research directions.

Battery Charge Discharge Machines are indispensable tools in the field of battery technology. Their ability to accurately test and evaluate batteries under controlled conditions supports the ongoing development of more efficient, durable, and safe energy storage solutions. As the demand for advanced batteries continues to grow, the role of BCDMs in research and development will remain crucial, driving innovations that power the technologies of tomorrow.

Fundamental Components of Battery Charge Discharge Machines (BCDM)

Battery Charge Discharge Machines (BCDM) are composed of several fundamental components that work in tandem to ensure accurate and reliable battery testing. These components include the power source, control unit or software architecture, load simulation and management systems, and safety features. Each component plays a critical role in the overall functionality and performance of the BCDM, contributing to its ability to deliver precise and repeatable test results.

Power Source Selection and Requirements

The power source is a crucial component of a BCDM, as it supplies the necessary energy to charge the battery and absorbs energy during discharge. The selection of an appropriate power source depends on several factors, including the voltage and current requirements of the batteries being tested, the desired precision and stability, and the overall capacity of the testing system. High-quality power sources should provide stable and noise-free output to ensure accurate measurements. Additionally, they must be capable of handling a wide range of power levels to accommodate different battery types and sizes, from small consumer electronics batteries to large automotive or industrial batteries.

Control Unit or Software Architecture

The control unit or software architecture is the brain of the BCDM, responsible for managing the charging and discharging processes, recording data, and ensuring the accuracy of the tests. Modern BCDMs utilize sophisticated software that can automate test sequences, monitor real-time performance, and store data for analysis. The control unit typically interfaces with the power source, load simulation system, and safety mechanisms to coordinate their functions. Advanced control software may also offer features such as programmable charge and discharge profiles, user-friendly interfaces, and remote operation capabilities. This enables researchers to design complex testing protocols and conduct comprehensive evaluations of battery performance.

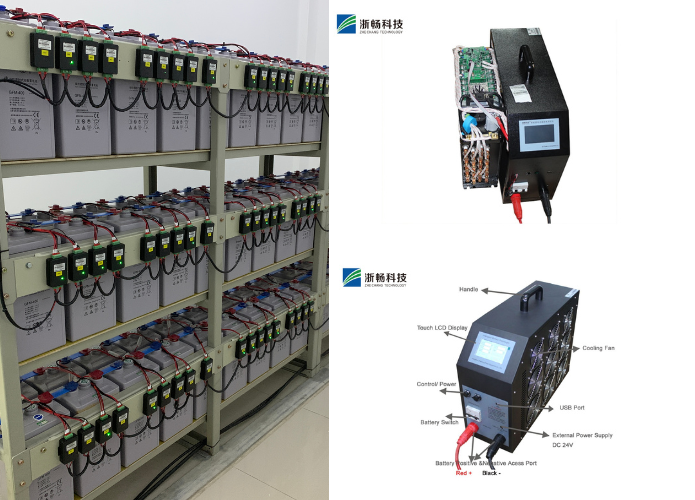

Load Simulation and Management Systems

Load simulation and management systems are essential for replicating the conditions that a battery will experience during actual use. These systems can simulate various loads, such as constant current, constant voltage, pulsed loads, and more complex dynamic profiles. By accurately replicating real-world operating conditions, load simulation systems help researchers understand how batteries perform under different scenarios. Effective load management is critical for ensuring that the BCDM can handle the power dissipation and thermal management requirements associated with high-power tests, preventing overheating and ensuring the longevity of the equipment.

Safety Features and Regulatory Compliance Considerations

Safety is a paramount concern in the design and operation of BCDMs, given the potential hazards associated with battery testing, such as thermal runaway, short circuits, and overcharging. Modern BCDMs incorporate a range of safety features, including overcurrent and overvoltage protection, thermal monitoring, and emergency shutdown mechanisms. These features help prevent accidents and protect both the equipment and the operator. Additionally, BCDMs must comply with relevant regulatory standards and guidelines to ensure safe operation. Regulatory compliance considerations may include adherence to standards such as UL, IEC, and ISO, which specify safety and performance requirements for battery testing equipment. Ensuring compliance with these standards is crucial for maintaining the integrity of the testing process and for gaining acceptance in the global market.

The fundamental components of Battery Charge Discharge Machines—power source, control unit or software architecture, load simulation and management systems, and safety features—are integral to their operation and effectiveness. Each component must be carefully designed and selected to ensure precise, reliable, and safe battery testing. As battery technology continues to advance, the development of BCDMs with enhanced capabilities and safety features will remain essential for supporting innovation and ensuring the performance and safety of next-generation batteries.

Working Principles of Battery Charge Discharge Machines (BCDM)

The working principles of Battery Charge Discharge Machines (BCDM) encompass the intricate processes involved in charging and discharging batteries, ensuring accurate measurement and analysis of battery performance. These principles are grounded in the dynamics of charging and discharging phases, voltage and current regulation, and the use of adaptive algorithms tailored to various battery chemistries. Additionally, the specifics of load simulation techniques and the impact of discharge rates on battery health and performance are critical components of BCDM operations.

Charging Phase Dynamics

During the charging phase, a BCDM controls the flow of electrical energy into the battery, ensuring it is stored efficiently and safely. The charging process typically involves multiple stages, including a constant current phase, where the battery is charged at a steady rate, and a constant voltage phase, where the voltage is held steady while the current gradually decreases. This approach helps prevent overcharging and extends the battery’s lifespan. The dynamics of this phase are crucial for optimizing the battery's capacity and ensuring it reaches its full charge without degradation.

Voltage and Current Regulation Mechanisms

Accurate regulation of voltage and current is fundamental to the operation of a BCDM. Voltage regulation ensures that the voltage applied to the battery does not exceed safe limits, while current regulation maintains a stable current flow, preventing overheating and damage. These mechanisms are typically managed through sophisticated control circuits and feedback systems that continuously monitor and adjust the output. Precise regulation is essential for achieving reliable and repeatable test results, which are critical for battery development and quality control.

Adaptive Charging Algorithms for Various Battery Chemistries

Different battery chemistries, such as lithium-ion, nickel-metal hydride, and lead-acid, require distinct charging protocols to maximize performance and longevity. Adaptive charging algorithms are employed by BCDMs to tailor the charging process to the specific characteristics of each battery type. These algorithms take into account factors such as the battery’s state of charge, temperature, and age, adjusting the charging parameters dynamically to optimize the process. This adaptability ensures that each battery is charged in the most efficient and effective manner, reducing the risk of overcharging or undercharging.

Discharging Phase Specifics

The discharging phase involves drawing energy from the battery under controlled conditions to evaluate its performance and capacity. This phase is critical for understanding how the battery will behave in real-world applications. During discharging, the BCDM monitors parameters such as voltage drop, current flow, and temperature, providing valuable data on the battery’s efficiency and health. The specifics of this phase include maintaining a consistent load and accurately measuring the battery’s output to assess its true capacity and discharge characteristics.

Load Simulation Techniques (Resistive, Regenerative, etc.)

Load simulation techniques are employed by BCDMs to mimic the conditions under which a battery will operate in real-world scenarios. Resistive load simulation involves using resistors to create a controlled load, while regenerative load simulation recycles the energy discharged from the battery back into the system, making the process more energy-efficient. These techniques help in evaluating how the battery performs under different types of loads, such as constant, pulsed, or dynamic loads. Accurate load simulation is essential for understanding the battery’s behavior and ensuring it meets the required performance standards.

Impact of Discharge Rates on Battery Health and Performance

The rate at which a battery is discharged can significantly impact its health and performance. High discharge rates can lead to increased internal resistance, higher temperatures, and accelerated degradation, reducing the battery’s lifespan and capacity. Conversely, low discharge rates may not adequately stress the battery, failing to reveal potential weaknesses. BCDMs allow for the controlled variation of discharge rates to study their effects on battery performance. Understanding these impacts helps in developing batteries that can withstand the demands of their intended applications while maintaining optimal performance and longevity.

The working principles of Battery Charge Discharge Machines are centered around the precise control and monitoring of charging and discharging processes. Through advanced voltage and current regulation, adaptive charging algorithms, accurate load simulation, and an understanding of discharge rate impacts, BCDMs play a crucial role in the development and optimization of modern battery technologies. These principles ensure that batteries are tested comprehensively, providing the data needed to enhance their performance, safety, and reliability.

Advanced Features and Technologies

Battery Charge Discharge Machines (BCDMs) are incorporating advanced features and technologies to enhance their capabilities in testing and optimizing battery performance. These advancements include real-time data acquisition and monitoring, automation with integration into smart grid technologies, and the application of predictive analytics and machine learning for battery performance prediction.

Real-time Data Acquisition and Monitoring Capabilities

Modern BCDMs are equipped with sophisticated sensors and data acquisition systems that enable real-time monitoring of key parameters during battery testing. These systems continuously capture data such as voltage, current, temperature, and impedance, providing researchers with instant insights into battery behavior and performance trends. Real-time monitoring allows for immediate adjustments to test parameters, ensuring accurate and reliable test results. Advanced visualization tools and data analytics software further enhance the interpretation of test data, enabling deeper analysis of battery characteristics and enabling faster decision-making in battery development and optimization processes.

Automation and Integration with Smart Grid Technologies

Automation plays a crucial role in enhancing the efficiency and scalability of BCDMs. Automated systems within BCDMs can autonomously control test sequences, adjust parameters based on predefined algorithms, and perform continuous testing operations without manual intervention. Integration with smart grid technologies enables BCDMs to interact with energy management systems, optimizing battery charging and discharging cycles based on grid demand and renewable energy availability. This integration supports the development of grid-scale energy storage solutions and facilitates the deployment of battery technologies that enhance grid stability, reliability, and efficiency.

Predictive Analytics and Machine Learning Applications for Battery Performance Prediction

The application of predictive analytics and machine learning represents a significant advancement in BCDM technology. These techniques analyze vast amounts of historical and real-time data to develop predictive models of battery behavior, performance degradation, and remaining useful life. Machine learning algorithms can identify patterns, correlations, and anomalies in battery performance data that traditional methods may overlook. By predicting performance under various operating conditions and aging scenarios, BCDMs equipped with predictive analytics empower researchers and engineers to optimize battery designs, improve cycle life, and enhance reliability. These capabilities are essential for developing next-generation batteries that meet the demanding requirements of electric vehicles, renewable energy storage, and other critical applications.

Applications and Use Cases

Battery Charge Discharge Machines (BCDM) find diverse applications across various industries, primarily focused on testing and evaluating battery performance under controlled conditions. These machines are instrumental in battery capacity testing and characterization, performance evaluation under different environmental conditions, cycle life testing, and degradation analysis, as well as in the validation of Battery Management Systems (BMS). Each application serves a crucial role in advancing battery technology and ensuring the reliability and safety of battery-powered devices and systems.

Battery Capacity Testing and Characterization

One of the primary applications of BCDMs is battery capacity testing and characterization. This involves measuring the maximum amount of energy that a battery can store and deliver under specific conditions. BCDMs conduct precise charge and discharge cycles while monitoring voltage, current, and temperature, providing accurate data on a battery’s capacity, efficiency, and energy density. This information is essential for manufacturers to optimize battery designs, improve performance, and meet the specific energy requirements of diverse applications, from consumer electronics to electric vehicles and renewable energy storage.

Performance Evaluation Under Different Environmental Conditions

BCDMs enable performance evaluation of batteries under various environmental conditions, including temperature extremes, humidity, and altitude. By simulating these conditions, researchers can assess how batteries perform in real-world applications where environmental factors may impact their efficiency and longevity. This testing helps identify optimal operating parameters and materials that can enhance battery performance and durability across different climates and usage scenarios.

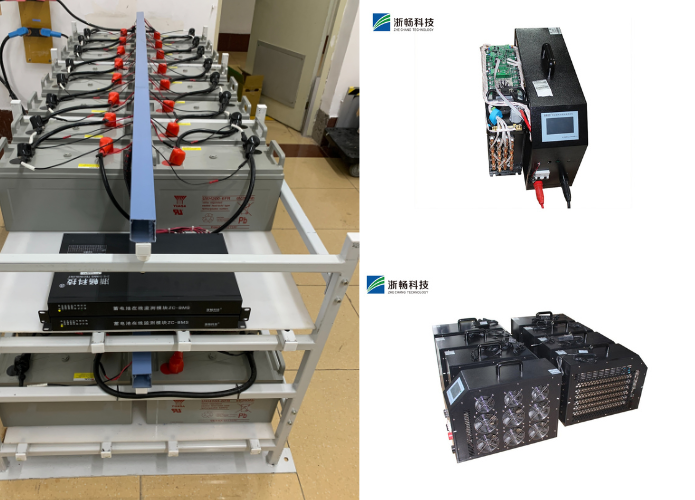

Cycle Life Testing and Degradation Analysis

Cycle life testing involves subjecting batteries to repeated charge and discharge cycles to simulate their lifespan and assess degradation over time. BCDMs accurately control and monitor these cycles, measuring changes in capacity, internal resistance, and efficiency. This data is crucial for predicting battery longevity, understanding degradation mechanisms such as capacity fade and electrode deterioration, and developing strategies to extend battery life. Cycle life testing is particularly valuable in industries requiring reliable, long-lasting batteries, such as automotive, aerospace, and grid energy storage.

Validation of Battery Management Systems (BMS)

Battery Management Systems (BMS) are critical for monitoring and controlling the performance and safety of batteries in complex applications. BCDMs are used to validate BMS functionality by simulating diverse operating conditions and load profiles. This validation ensures that BMS algorithms accurately manage battery charging, discharging, and thermal management, preventing overcharging, overheating, and other potential hazards. By testing BMS under controlled conditions, BCDMs verify their reliability and effectiveness, supporting the development of safer and more efficient battery-powered systems.

Benefits and Advantages

Battery Charge Discharge Machines (BCDM) offer significant benefits and advantages that contribute to the development, optimization, and reliability of battery technologies. These advantages include precision control over charging and discharging parameters, standardized testing protocols, reproducibility of results, and cost efficiency in battery development.

Precision Control Over Charging and Discharging Parameters

One of the primary advantages of BCDMs is their ability to provide precise control over charging and discharging parameters. These machines can accurately regulate voltage, current, and temperature during battery testing, ensuring that test conditions closely mimic real-world usage scenarios. This precision control allows researchers and engineers to optimize battery performance, maximize energy efficiency, and minimize the risk of damage or degradation. By fine-tuning these parameters, BCDMs enable the development of batteries that meet stringent performance criteria for diverse applications, from portable electronics to electric vehicles and renewable energy storage systems.

Standardized Testing Protocols and Reproducibility of Results

BCDMs facilitate the implementation of standardized testing protocols, ensuring consistency and reproducibility of results across different laboratories and testing facilities. Standardization is crucial for comparing battery performance data, validating new technologies, and meeting regulatory requirements. BCDMs adhere to established testing standards such as those set by organizations like ASTM International and IEC, which define protocols for capacity testing, cycle life evaluation, and safety assessments. This adherence to standards enhances confidence in the reliability and accuracy of test data, supporting informed decision-making in battery development and certification processes.

Cost Efficiency in Battery Development and Optimization

BCDMs contribute to cost efficiency in battery development by streamlining testing processes and reducing the need for iterative physical testing. These machines enable rapid evaluation of battery prototypes, identifying optimal designs and materials early in the development cycle. By accelerating testing timelines and minimizing the number of physical prototypes required, BCDMs help manufacturers save time and resources. Furthermore, the ability to simulate diverse operating conditions and usage scenarios mitigates risks associated with field testing, such as equipment damage or safety hazards. This cost-effective approach supports innovation in battery technology, enabling continuous improvement and the introduction of advanced energy storage solutions to the market.

Challenges and Limitations

While Battery Charge Discharge Machines (BCDM) offer significant advantages in battery testing and development, they also face several challenges and limitations that need to be addressed to ensure optimal performance and safety.

Heat Dissipation and Thermal Management During High-Power Operations

One of the primary challenges with BCDMs is managing heat dissipation, particularly during high-power operations such as rapid charging or discharging cycles. Batteries can generate significant heat under these conditions, which can affect performance and safety. Effective thermal management systems are essential to regulate temperatures and prevent overheating, which can lead to accelerated degradation or even thermal runaway. Ensuring adequate cooling and heat dissipation mechanisms within BCDMs is crucial for maintaining accurate test conditions and prolonging equipment lifespan.

Safety Protocols for Handling High-Energy Density Batteries

Another critical challenge is implementing robust safety protocols to handle high-energy-density batteries safely. Batteries with higher energy densities, such as lithium-ion batteries used in electric vehicles and portable electronics, pose greater risks if mishandled or subjected to improper charging or discharging conditions. BCDMs must incorporate comprehensive safety features, including overcurrent protection, voltage monitoring, and emergency shutdown mechanisms, to mitigate these risks effectively. Compliance with stringent safety standards and regulations is essential to ensure the protection of personnel and equipment during battery testing operations.

Complexity in Integrating Diverse Battery Chemistries and Form Factors

The diversity of battery chemistries and form factors presents a significant challenge for BCDMs. Different battery chemistries, such as lithium-ion, nickel-metal hydride, and lead-acid, have distinct characteristics and performance requirements that necessitate specialized testing protocols and equipment configurations. Integrating BCDMs to accommodate various battery sizes, shapes, and electrical specifications adds complexity to testing procedures and equipment design. Moreover, as new battery technologies emerge, BCDMs must adapt to support the testing and evaluation of these innovations effectively. Ensuring versatility and compatibility across diverse battery types remains an ongoing challenge in battery testing and development.

Future Directions

As Battery Charge Discharge Machines (BCDMs) continue to evolve, several future directions are shaping their development, influenced by innovations in energy storage technologies, sustainable practices, and the potential for modular, scalable designs.

Innovations in Energy Storage Technologies Influencing BCDM Development

The rapid evolution of energy storage technologies, driven by advancements in materials science, nanotechnology, and renewable energy integration, is reshaping the landscape of BCDM development. Innovations such as solid-state batteries, flow batteries, and advanced lithium-ion chemistries are placing new demands on testing equipment to accurately assess performance metrics such as energy density, cycle life, and safety. Future BCDMs are likely to incorporate enhanced capabilities for testing and characterizing these emerging technologies, including higher precision control over charging/discharging parameters, compatibility with diverse chemistries, and real-time data analytics to support rapid prototyping and optimization.

Sustainable Battery Testing Practices in Alignment with Environmental Goals

There is a growing emphasis on sustainable practices within the battery industry, prompting a shift towards more environmentally friendly testing methodologies and equipment. Future BCDMs are expected to integrate energy-efficient designs, reduce resource consumption, and incorporate recyclable materials to minimize environmental impact. Moreover, advancements in energy recovery systems within BCDMs—such as regenerative load simulation techniques—can contribute to reducing overall energy consumption and operational costs while aligning with global sustainability goals. Implementing lifecycle assessments and adhering to eco-friendly standards will be crucial in ensuring that BCDM development supports the broader objectives of environmental stewardship and resource conservation.

Potential for Modular and Scalable BCDM Designs for Diverse Applications

Modularity and scalability are key considerations for future BCDM designs, enabling versatility across a wide range of applications and battery types. Modular BCDMs can accommodate varying sizes, form factors, and electrical specifications, allowing for flexible configurations tailored to specific testing requirements. Scalable designs facilitate the expansion of testing capabilities to handle larger throughput and more complex testing scenarios without compromising precision or reliability. This scalability is particularly beneficial in industries such as automotive, renewable energy, and grid storage, where demand for high-performance, reliable batteries continues to grow. By adopting modular and scalable architectures, future BCDMs can support innovation and accelerate the development of next-generation energy storage solutions for diverse applications.

Conclusion

In conclusion, Battery Charge Discharge Machines (BCDMs) represent crucial tools at the forefront of battery technology development and optimization. These machines enable precise control over charging and discharging parameters, standardized testing protocols, and reproducibility of results, all of which are essential for advancing energy storage solutions across various industries. However, BCDMs also face challenges such as heat dissipation, safety considerations for high-energy-density batteries, and the complexity of integrating diverse battery chemistries and form factors.

Looking ahead, future directions for BCDM development are promising. Innovations in energy storage technologies are driving the need for enhanced testing capabilities, including compatibility with new battery chemistries and scalable designs that can accommodate diverse applications. Sustainable practices are becoming increasingly important, influencing the adoption of eco-friendly testing methodologies and equipment designs aligned with environmental goals. Modular and scalable BCDM architectures offer flexibility and adaptability, supporting ongoing advancements in battery performance and reliability.

As the demand for efficient, high-capacity batteries continues to grow—especially in sectors such as electric vehicles, renewable energy storage, and portable electronics—BCDMs will play a pivotal role in ensuring the development of safe, reliable, and sustainable energy storage solutions. By addressing current challenges and embracing future innovations, BCDMs are poised to drive significant advancements in battery technology, contributing to a cleaner, more sustainable energy future for global markets and society as a whole.

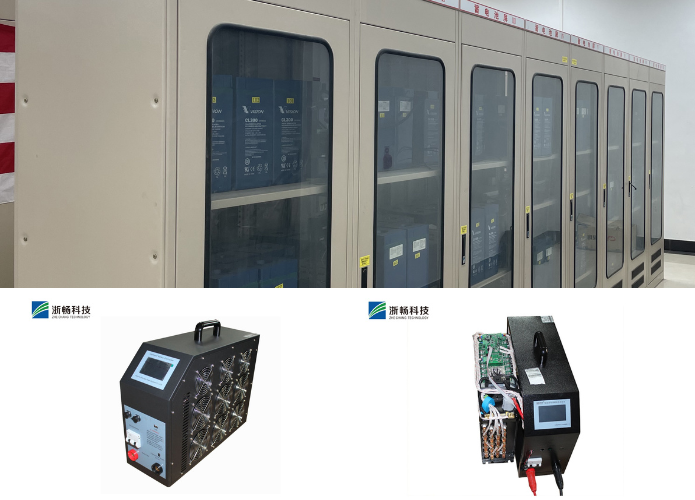

Zhechang is a professional supplier specializing in Battery Charge Discharge Machines (BCDMs), offering a comprehensive range of advanced testing equipment designed to meet the diverse needs of battery research, development, and manufacturing industries. With a commitment to quality and innovation, Zhechang provides state-of-the-art BCDMs equipped with precision control systems, real-time monitoring capabilities, and automated features to ensure accurate and reliable battery testing. Their extensive expertise and dedication to technological advancement make them a trusted partner for organizations seeking to optimize battery performance, enhance efficiency, and achieve sustainable energy solutions.

Popular Battery Tester

Popular Battery Tester

Latest News

Latest News

Get Price of Battery Tester

Get Price of Battery Tester

Address:

Floor 3, Building 1, No.1418-60, Moganshan road, Hangzhou city, Zhejiang Province, China.310015