Comparison of Demands for Battery Testers in Different Application Scenarios

Overview of Battery Testers and Their Significance

Batteries power a wide range of modern applications, from small consumer electronics to massive energy storage systems. As industries shift toward electrification and sustainability, the reliability of batteries becomes a crucial factor in ensuring uninterrupted operations. This is where battery testers come into play.

Battery testers are essential diagnostic tools used to evaluate a battery’s state of charge (SoC), state of health (SoH), capacity, internal resistance, and overall performance. Regular testing allows users to identify weak or failing batteries before they cause critical failures, which is especially important in industries such as electric vehicles (EVs), aerospace, telecommunications, and renewable energy storage.

The demand for battery testers is growing due to several factors:

- The global push toward renewable energy storage and grid stabilization.

- The rise of electric mobility and the need for efficient EV battery management.

- The increasing reliance on uninterrupted power supplies in industries such as healthcare, data centers, and manufacturing.

- The growing consumer electronics market, where battery life is a key factor in product quality.

With different industries relying on batteries of various chemistries, voltages, and capacities, battery testers must be tailored to meet specific testing requirements. In this article, we will explore different types of battery testers, key testing metrics, and how their demand varies across application scenarios.

Types of Battery Testers

Battery testers are categorized based on their functionality, testing methods, and the specific battery characteristics they measure. Some testers are designed for quick, basic checks, while others perform in-depth analyses for industrial and high-performance applications.

1. Voltage Testers

Voltage testers measure a battery’s open-circuit voltage (OCV) to estimate its charge level. These testers are commonly used in consumer electronics and general-purpose battery maintenance. While voltage readings provide a basic assessment of a battery’s condition, they do not give a complete picture of its health or remaining capacity.

2. Capacity Testers

Capacity testers evaluate how much energy a battery can store and deliver over a full charge-discharge cycle. These testers are crucial for applications where battery longevity is a concern, such as electric vehicles, renewable energy storage systems, and industrial backup power.

3. Internal Resistance Testers

Internal resistance testers measure a battery’s resistance to electrical flow, which increases as the battery ages. High internal resistance indicates a decline in battery efficiency and potential failure. These testers are widely used in automotive, UPS (uninterruptible power supply) systems, and telecom applications.

4. Load Testers

Load testers assess battery performance by applying a specific electrical load and measuring its response. This method simulates real-world conditions and is often used in the automotive industry to check the cranking power of lead-acid batteries.

5. Conductance Testers

Conductance testers estimate battery health by measuring its electrical conductance. This method is faster and less invasive than full discharge tests, making it ideal for quick assessments in fleet management, industrial power systems, and grid energy storage.

6. Smart Battery Testers

Modern battery testers integrate data logging, Bluetooth connectivity, and AI-based analytics for real-time monitoring. These testers are useful in predictive maintenance for EV fleets, renewable energy grids, and mission-critical power systems.

Key Metrics for Battery Testing

To assess a battery’s performance and reliability, several key parameters are measured:

1. Voltage (V)

The voltage of a battery gives an indication of its charge level and operational readiness. However, voltage alone is not a reliable measure of battery health, as aging and degradation may still occur despite normal voltage readings.

2. Capacity (Ah or Wh)

Capacity refers to the total amount of energy a battery can store and deliver. Over time, a battery’s capacity decreases due to chemical aging and repeated charge-discharge cycles.

3. Internal Resistance (mΩ)

Higher internal resistance leads to reduced efficiency and overheating, which can cause premature failure. This metric is critical for applications requiring high power output, such as EVs and aerospace systems.

4. State of Charge (SoC)

SoC represents the remaining energy in a battery as a percentage of its full capacity. It is essential for battery management systems (BMS) in electric vehicles and renewable energy storage.

5. State of Health (SoH)

SoH measures a battery’s overall condition compared to its original specifications. It is a key factor in determining when a battery needs replacement in industrial and automotive applications.

6. Cycle Life

This metric tracks the number of charge-discharge cycles a battery can endure before its performance significantly declines.

7. Temperature Sensitivity

Extreme temperatures affect battery performance and longevity, making thermal testing an essential part of battery evaluation in aerospace, defense, and automotive applications.

Application Scenarios

Battery testers are used across multiple industries, each with unique requirements:

a. Consumer Electronics

Batteries Used: Lithium-ion (Li-ion), alkaline, nickel-metal hydride (NiMH).

Testing Needs: Quick voltage checks, capacity assessments, and charge-discharge cycle tests.

Common Testers: Voltage testers, smart testers.

b. Automotive (EVs & Conventional Vehicles)

Batteries Used: Lead-acid, lithium-ion, solid-state (emerging).

Testing Needs: Load testing, internal resistance measurement, SoC and SoH evaluations.

Common Testers: Load testers, conductance testers, smart testers.

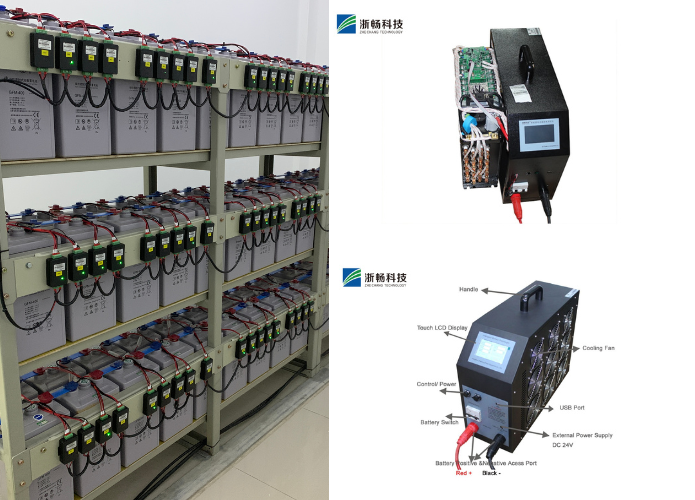

c. Renewable Energy Storage

Batteries Used: Li-ion, lithium-iron-phosphate (LiFePO4), lead-acid.

Testing Needs: Long-term cycle testing, capacity assessment, predictive maintenance.

Common Testers: Capacity testers, smart testers with cloud analytics.

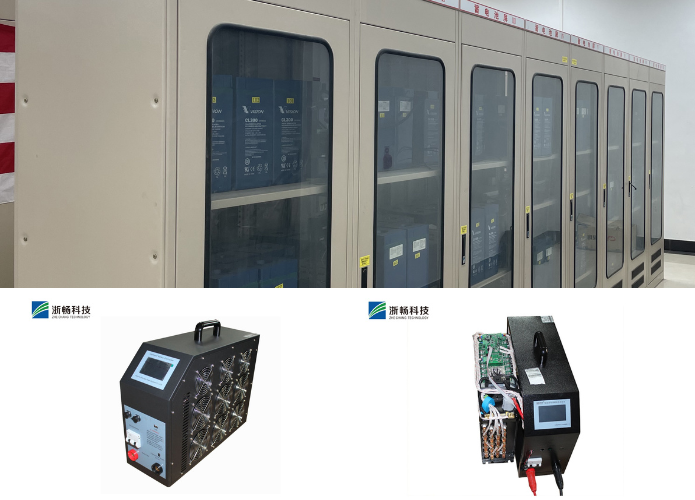

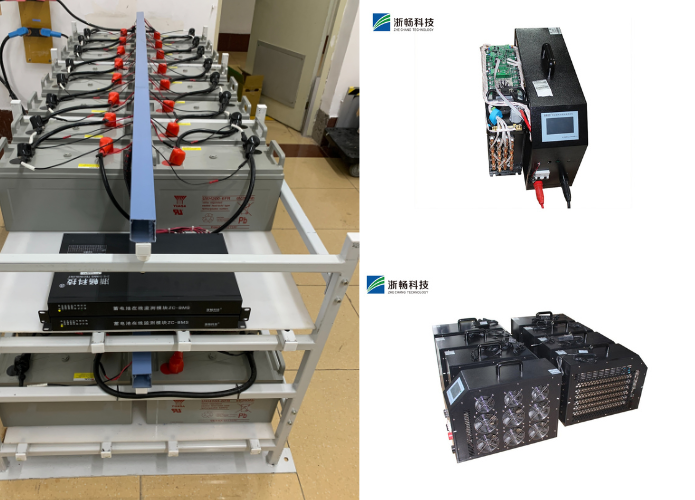

d. Industrial & Telecom Backup Power

Batteries Used: VRLA, lithium-ion.

Testing Needs: Internal resistance monitoring, voltage stability checks.

Common Testers: Internal resistance testers, conductance testers.

e. Aerospace & Defense

Batteries Used: High-density lithium-based, Ni-Cd.

Testing Needs: Performance evaluation in extreme conditions, SoH monitoring.

Common Testers: High-precision internal resistance testers, smart testers.

f. Medical Devices

Batteries Used: Li-ion, NiMH, rechargeable alkaline.

Testing Needs: Compact, non-invasive testers to assess battery health.

Common Testers: Voltage testers, conductance testers.

Comparison of Testing Demands

The battery testing requirements vary significantly across industries. The following table provides a comparative analysis:

|

Industry |

Key Testing Metrics |

Tester Type |

Testing Frequency |

|

Consumer Electronics |

Voltage, capacity |

Voltage testers, smart testers |

Occasional |

|

Automotive |

SoC, SoH, load testing |

Load testers, conductance testers |

Regular |

|

Renewable Energy |

Capacity, cycle life, SoH |

Capacity testers, smart testers |

Continuous monitoring |

|

Industrial Power |

Internal resistance, voltage |

Internal resistance testers |

Periodic |

|

Aerospace & Defense |

High-precision voltage, SoH |

Smart testers, thermal testers |

Mission-critical |

|

Medical Devices |

Voltage, low-resistance tests |

Compact voltage testers |

Regular |

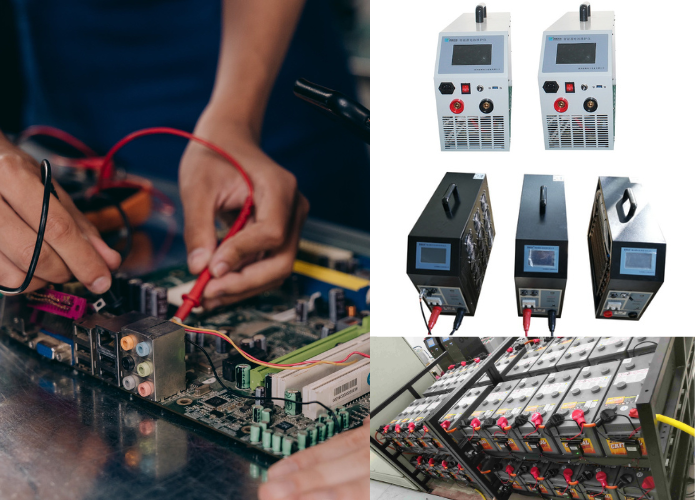

Trends in Battery Tester Development

As battery technology evolves, battery testers are also advancing to meet new challenges. The following trends are shaping the industry:

a. Integration of AI & IoT

AI-powered battery testers can predict failures before they occur.

IoT-enabled testers allow remote monitoring and diagnostics.

b. Advanced Thermal Testing

As high-energy-density batteries become common, thermal analysis is increasingly important to prevent overheating and fires.

c. Wireless and Portable Testers

Handheld, wireless testers are gaining popularity, especially for field applications in automotive and industrial settings.

d. Compatibility with Emerging Battery Technologies

New testers are being developed to support solid-state batteries, sodium-ion batteries, and ultra-fast charging lithium-ion batteries.

e. Enhanced Data Logging & Cloud Connectivity

Battery testers are integrating cloud-based analytics to store historical data for long-term performance tracking.

Conclusion

Battery testers are essential across various industries, with different application scenarios demanding specialized testing methodologies. While consumer electronics require basic voltage testing, automotive and industrial applications rely on advanced SoC and SoH evaluations. The rise of electric vehicles, renewable energy storage, and mission-critical power systems is pushing the need for smart, AI-driven, and IoT-enabled battery testers.

As battery technologies continue to evolve, so will the tools used to evaluate them, ensuring safer, more efficient, and longer-lasting energy solutions across industries.

Popular Battery Tester

Popular Battery Tester

Latest News

Latest News

Get Price of Battery Tester

Get Price of Battery Tester

Address:

Floor 3, Building 1, No.1418-60, Moganshan road, Hangzhou city, Zhejiang Province, China.310015