How to Test Battery Capacity?

Testing battery capacity is crucial for assessing the performance and reliability of batteries across various applications. Whether for consumer electronics, electric vehicles, or renewable energy storage, understanding the true capacity of a battery helps in optimizing its usage and predicting its lifespan. This process involves measuring how much charge a battery can store and deliver under specific conditions, providing valuable insights into its health and efficiency.

Importance of Testing Battery Capacity

The importance of testing battery capacity lies in ensuring reliable performance and longevity. Batteries degrade over time due to various factors such as usage patterns, environmental conditions, and charging practices. By regularly testing capacity, users can identify early signs of degradation, allowing for proactive maintenance or replacement before performance issues arise. This proactive approach not only optimizes the efficiency of devices or systems but also minimizes downtime and potential safety risks associated with failing batteries.

Types of Batteries to Test

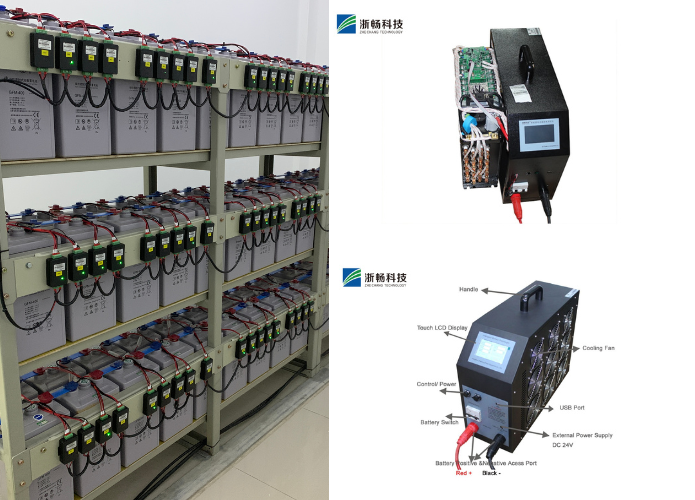

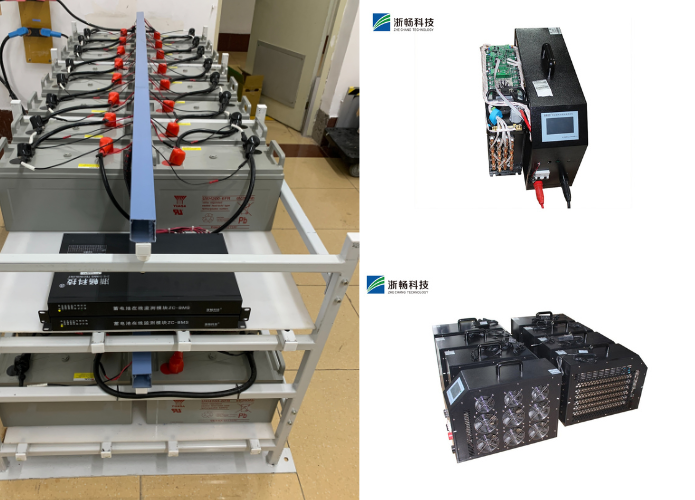

Various types of batteries require capacity testing, each with unique characteristics and performance metrics. Common types include lithium-ion, lead-acid, nickel-metal hydride (NiMH), and nickel-cadmium (NiCd) batteries. Each type differs in voltage profiles, charging requirements, and discharge characteristics, necessitating tailored testing methods for accurate assessment. For instance, lithium-ion batteries, widely used in portable electronics and electric vehicles, require precise monitoring of voltage drop and internal resistance to gauge capacity accurately. On the other hand, lead-acid batteries, commonly found in automotive and backup power applications, require periodic capacity tests to maintain optimal performance and prevent premature failure.

Understanding the intricacies of battery capacity testing is essential for maximizing the reliability and efficiency of battery-powered devices and systems. By adopting systematic testing methods and monitoring battery health regularly, users can prolong battery life, enhance operational performance, and mitigate risks associated with unexpected failures.

Preparation

Preparing for battery capacity testing involves gathering essential tools and equipment, as well as understanding and implementing crucial safety precautions to ensure accurate and safe testing procedures.

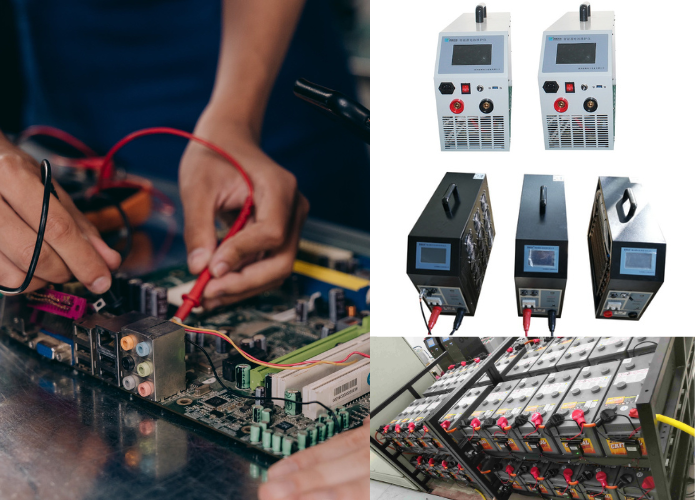

1. Gather Necessary Tools and Equipment

Multimeter or Battery Tester: A multimeter is essential for measuring voltage, current, and resistance in batteries. Alternatively, a dedicated battery tester provides specific readings related to battery capacity and health, making it ideal for detailed assessments.

Safety Gear: Safety gear such as gloves and safety glasses protects against potential hazards during handling and testing. Gloves prevent direct contact with chemicals or corrosive materials that may leak from batteries, while safety glasses shield the eyes from splashes or small debris.

Battery Charger (if needed): Some testing methods, particularly those involving discharge and recharge cycles, may require a battery charger. This ensures batteries are adequately charged before testing and can be recharged for subsequent tests if necessary.

2. Understand Safety Precautions

Handling of Batteries: Proper handling of batteries is critical to prevent physical injury or chemical exposure. Always handle batteries with care, avoiding drops or impacts that could damage them and cause leakage. When handling, grip batteries firmly and avoid touching exposed terminals to prevent short circuits.

Avoiding Short Circuits: Short circuits can occur if battery terminals come into contact with conductive materials such as metal tools or surfaces. To prevent short circuits, ensure batteries are isolated when not in use and use insulated tools when necessary. Always check and confirm connections are secure before proceeding with testing.

Proper Ventilation: During testing, especially when dealing with older or potentially damaged batteries, ensure adequate ventilation in the testing area. This helps disperse any gases that may be emitted during charging or discharging processes, reducing the risk of exposure to harmful fumes and maintaining a safe testing environment.

Testing Methods

Testing battery capacity involves employing various methods to measure and assess its performance under different conditions. Each method provides unique insights into the battery's health and efficiency, helping users make informed decisions about maintenance or replacement.

1. Open Circuit Voltage (OCV) Method

The Open Circuit Voltage (OCV) method is a straightforward way to estimate a battery's state of charge without applying a load. Here’s how to perform and interpret an OCV test:

Steps to Perform OCV Test: Begin by letting the battery rest for several hours after charging or discharging to stabilize its voltage. Use a multimeter to measure the battery’s voltage across its terminals. Record this voltage as the OCV.

Interpreting Voltage Readings: OCV readings provide a general indication of the battery's state of charge. Higher voltages typically indicate a higher charge level, while lower voltages suggest a lower charge. However, accurate interpretation may require comparing the measured OCV against a manufacturer’s specification or reference values for the specific battery type.

2. Load Testing Method

The Load Testing method involves applying a controlled electrical load to the battery and monitoring its performance under load conditions:

Setting Up the Load Tester: Connect a suitable load tester or resistor to the battery terminals. The load should be appropriate for the battery type and capacity being tested. Ensure all connections are secure and capable of handling the expected current without overheating or damage.

Performing the Load Test: Activate the load and monitor the battery's voltage over a specified period. Note the initial voltage drop upon applying the load and observe how the voltage stabilizes or decreases over time. Measure the duration for which the battery maintains a usable voltage under load before reaching a predefined cutoff voltage.

Interpreting Results: Analyze the voltage drop during the test and the duration for which the battery remains above a specified threshold voltage. These parameters help assess the battery's capacity to deliver power under load conditions. Interpretation may involve comparing the observed performance with expected values based on the battery’s rating or previous test results.

3. Internal Resistance Measurement

Measuring internal resistance provides insights into the battery’s condition and its ability to deliver current efficiently:

Using a Battery Analyzer or Multimeter: Use a specialized battery analyzer or a multimeter capable of measuring internal resistance. Apply a known current through the battery and measure the voltage drop across its terminals. Calculate the internal resistance using Ohm's law (R = V/I), where V is the voltage drop and I is the current.

Understanding Internal Resistance Values: Lower internal resistance indicates better conductivity within the battery, allowing for more efficient energy transfer and lower heat generation during operation. Higher internal resistance may indicate aging, damage, or poor cell connections within the battery, affecting its performance and capacity.

Analyzing Results

After conducting battery capacity tests using various methods, it's essential to analyze the results effectively to understand the battery's current state, performance characteristics, and potential future reliability.

1. Comparing Measured Capacity with Rated Capacity

Comparing the measured capacity with the battery’s rated capacity provides insights into its current performance relative to its designed specifications:

Steps for Comparison: Calculate the measured capacity obtained from the testing methods (e.g., OCV, Load Testing) and compare it against the manufacturer's rated capacity. This comparison helps determine whether the battery is performing as expected or if there is a deviation due to degradation or other factors.

Interpreting Differences: Minor discrepancies between measured and rated capacities are normal and may result from environmental conditions, usage patterns, or calibration variations. Significant deviations, however, could indicate issues such as battery aging, capacity loss, or incorrect charging practices.

2. Identifying Degradation or Issues

Identifying degradation or issues involves assessing changes in battery performance over time or under different operating conditions:

Signs of Degradation: Look for signs such as decreased capacity under load, increased internal resistance, or higher voltage drops during discharge. These indicators suggest that the battery may be aging or experiencing internal damage, affecting its ability to store and deliver energy efficiently.

Testing Consistency: Repeat capacity tests periodically to track changes in performance. Consistent or worsening results over time indicate progressive degradation, while sudden changes may indicate acute issues like cell damage or electrical faults.

3. Estimating Battery Health and Remaining Lifespan

Estimating battery health and remaining lifespan involves predicting how much longer the battery can function effectively based on current test results and historical performance data:

Health Assessment: Use measured capacity, internal resistance values, and voltage behaviors under load to assess overall battery health. A healthy battery typically exhibits stable performance metrics within expected ranges, whereas degraded batteries show irregularities or reduced performance metrics.

Lifespan Prediction: Consider factors such as operating conditions, usage patterns, and historical performance trends when estimating remaining battery lifespan. Predictive models or manufacturer specifications can provide insights into typical lifecycle expectations, helping to plan for maintenance or replacement schedules.

Conclusion

In conclusion, thorough and systematic battery capacity testing is essential for maintaining optimal performance and reliability across a range of applications, from consumer electronics to industrial systems. By employing methods like Open Circuit Voltage (OCV), Load Testing, and Internal Resistance Measurement, users can gain valuable insights into a battery's current state and health.

The process of analyzing test results, including comparing measured capacity with rated capacity, identifying degradation or issues, and estimating remaining lifespan, provides crucial information for decision-making. It allows users to determine whether a battery meets expected performance standards, identify potential maintenance needs or risks of failure, and plan effectively for future replacements or upgrades.

Regular testing and analysis not only enhance operational efficiency but also contribute to safety by minimizing the risks associated with faulty or deteriorating batteries. By staying proactive in monitoring battery health and performance, stakeholders can optimize usage, extend battery life, and reduce overall operational costs.

Ultimately, the insights gained from thorough analysis enable informed decisions that support sustainable and reliable battery management practices, ensuring continued performance excellence and meeting the demands of evolving technological and industrial landscapes.

Additional Tips

Effective battery management goes beyond initial testing and analysis. Implementing appropriate frequency of testing and adopting maintenance and care practices are essential for maximizing battery longevity and performance.

1. Frequency of Testing

Determining the frequency of battery testing depends on several factors, including usage intensity, environmental conditions, and criticality of the application:

- Regular Monitoring: For critical applications or batteries in constant use, regular monitoring every few months may be necessary to detect early signs of degradation or performance decline.

- Periodic Assessment: Less critical applications or batteries with lower usage may require testing on an annual basis or when specific performance issues arise.

- By establishing a testing schedule based on these factors, users can proactively manage battery health, identify potential issues early, and optimize performance over time.

2. Maintenance and Care Practices

Proper maintenance and care practices are crucial for extending battery life and ensuring consistent performance:

- Temperature Control: Avoid exposing batteries to extreme temperatures, as both heat and cold can degrade performance and shorten lifespan. Store batteries in cool, dry environments when not in use.

- Proper Charging: Follow manufacturer guidelines for charging cycles and avoid overcharging or deep discharges, which can accelerate battery degradation. Use chargers specifically designed for the battery type to optimize charging efficiency.

- Cleaning and Inspection: Regularly inspect batteries for signs of corrosion, leaks, or physical damage. Clean terminals and contacts with a suitable cleaner and ensure connections are secure to prevent performance issues or safety hazards.

- Storage Considerations: If storing batteries for extended periods, ensure they are partially charged and in a stable environment to minimize self-discharge and maintain readiness for future use.

By integrating these maintenance and care practices into battery management strategies, users can enhance reliability, prolong lifespan, and mitigate risks associated with unexpected failures or performance declines. This proactive approach not only optimizes operational efficiency but also supports sustainable use of battery-powered devices across various applications.

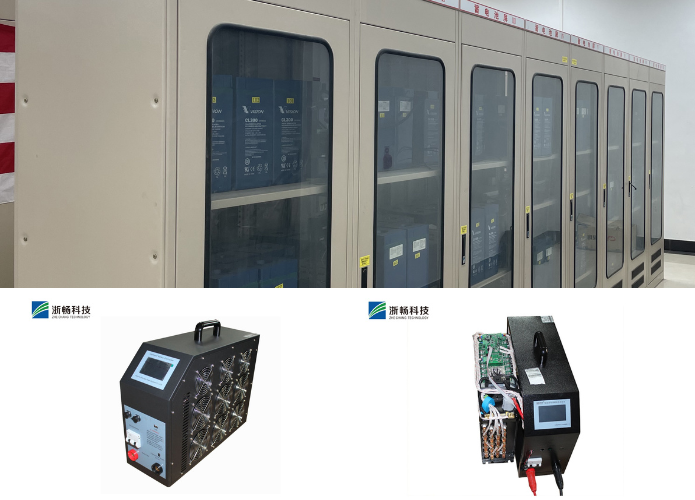

Popular Battery Tester

Popular Battery Tester

Latest News

Latest News

Get Price of Battery Tester

Get Price of Battery Tester

Address:

Floor 3, Building 1, No.1418-60, Moganshan road, Hangzhou city, Zhejiang Province, China.310015