How Do You Test a Deep Cycle Battery?

Testing deep cycle batteries is essential for maintaining their performance and extending their lifespan. These batteries are widely used in applications requiring consistent and reliable power, such as marine vehicles, solar power systems, and RVs. Ensuring their optimal function is crucial for these applications, where power failure can have significant consequences. This article will delve into various methods for testing deep cycle batteries, highlighting the importance of regular testing and monitoring. We'll explore the use of specialized tools such as deep cycle battery testers, load testers, and analyzers, each providing valuable insights into the battery's condition. By understanding and implementing these testing techniques, users can detect potential issues early, optimize battery usage, and prevent unexpected failures. Whether for professional or personal use, knowing how to properly test deep cycle batteries is key to achieving long-term reliability and efficiency in power systems.

What is a Deep Cycle Battery?

Deep cycle batteries are engineered to deliver a steady, sustained amount of current over extended periods, making them ideal for applications where consistent power is essential. Unlike starter batteries, which are designed to provide a high burst of energy for short durations to start an engine, deep cycle batteries are built to be discharged and recharged repeatedly without suffering significant wear or degradation. This characteristic allows them to maintain their performance and longevity even after numerous charge and discharge cycles. Deep cycle batteries are particularly well-suited for applications such as marine vehicles, solar power systems, and recreational vehicles (RVs), where a reliable and continuous power supply is crucial. Their robust design ensures that they can handle prolonged use and deep discharges, making them a reliable choice for demanding power needs.

Why Test Deep Cycle Batteries?

Regularly testing deep cycle batteries is essential for several important reasons:

- Prolonging Battery Life: Routine testing allows you to identify potential issues before they become serious problems. By addressing these issues early, you can take corrective measures to extend the battery's lifespan, ensuring that it continues to perform effectively over time.

- Ensuring Safety: Faulty batteries can pose significant safety risks, including leakage, overheating, and even potential fire hazards. Regular testing helps detect these risks early, allowing you to address them promptly and maintain a safe environment.

- Maintaining Performance: Consistent testing ensures that the battery is operating at its optimal level. This helps in verifying that the battery delivers reliable power when needed, avoiding unexpected power failures and ensuring that the battery meets the demands of your specific application.

Overall, regular testing is key to achieving the best performance, safety, and longevity from your deep cycle batteries.

How to Choose a Deep Cycle Battery Tester?

Selecting the right battery tester is essential for obtaining accurate and reliable results. Here are some key features to consider when choosing a tester:

- Accuracy: Ensure the tester provides precise readings of voltage, current, and resistance. Accurate measurements are critical for diagnosing battery health and performance effectively.

- Ease of Use: Look for a tester with a user-friendly interface and clear, easy-to-read displays. Simplicity in operation can reduce the likelihood of errors and make the testing process more efficient.

- Versatility: Choose a tester that is compatible with a range of battery types and sizes. A versatile tester can handle various applications, from deep cycle batteries to other battery configurations, providing more flexibility in your testing needs.

- Durability: Opt for a tester built to withstand rugged conditions, especially if it will be used in outdoor or demanding environments. A durable tester ensures longevity and reliability, even in harsh or challenging settings.

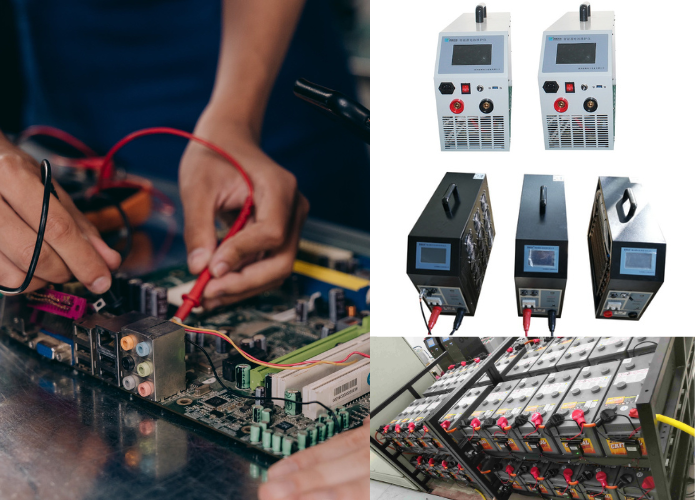

Types of Deep Cycle Battery Testers

Various tools are available for testing deep cycle batteries, each offering distinct functionalities to evaluate the battery's condition:

- Load Testers: Load testers simulate the actual load on a battery to assess its performance under stress. By applying a specific load, they measure the battery's ability to maintain voltage and supply current, which helps in identifying weak or failing cells.

- Battery Analyzers: Battery analyzers offer a more comprehensive analysis of the battery's condition. They provide detailed information on the state of health, capacity, internal resistance, and overall performance. This in-depth data allows for a more accurate assessment of the battery's longevity and reliability.

- Digital Multimeters: Although not specifically designed for battery testing, digital multimeters can measure voltage, offering a basic health check. They are useful for quickly checking the battery's charge status and identifying potential issues, such as undercharging or overcharging.

These tools, when used together, provide a thorough evaluation of a deep cycle battery's condition, helping to ensure its optimal performance and longevity.

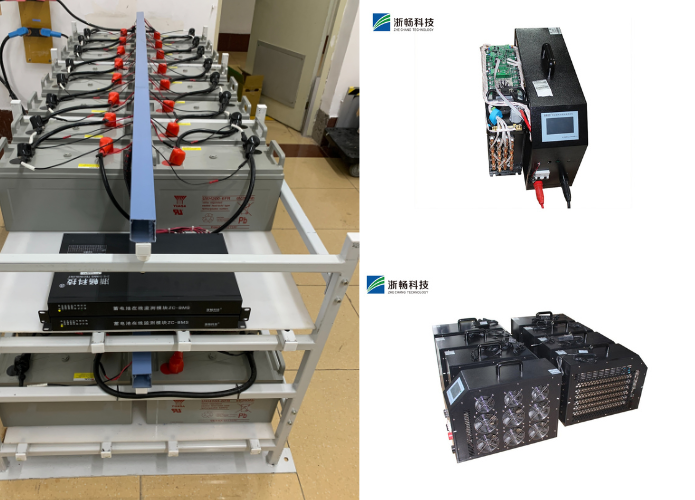

Deep Cycle Battery Load Tester

A load tester is an invaluable tool for evaluating a battery's capacity to hold a charge and deliver power effectively. By applying a controlled load to the battery, it simulates real-world conditions and measures the battery's voltage response. This testing method is particularly useful for identifying batteries that may seem functional when tested without a load but actually fail to perform adequately under operational conditions.

The load tester helps detect issues such as weak or deteriorated cells that might not be evident through basic voltage checks alone. By revealing how a battery responds to stress, it provides a more accurate assessment of the battery's true condition, ensuring that only reliable batteries are used in critical applications. This capability is essential for maintaining system performance and avoiding unexpected power failures.

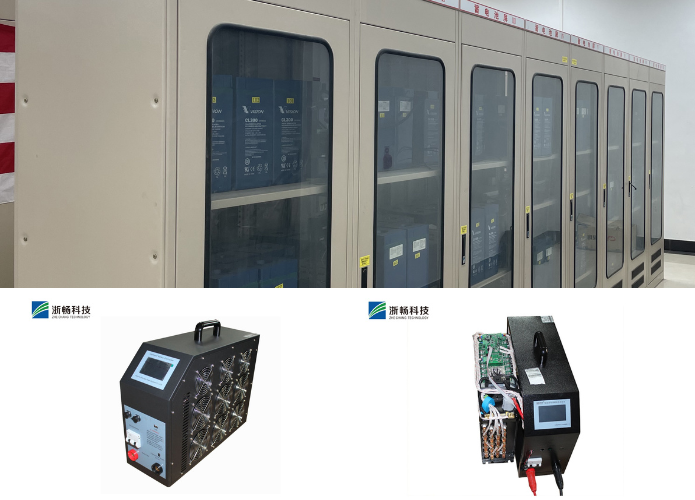

Battery Tester for Deep Cycle Battery

Testers designed specifically for deep cycle batteries provide detailed and crucial information about the battery's condition, offering features that go beyond basic testing. Some of the key features often included are:

- State of Charge (SOC) Measurement: This feature determines the current charge level of the battery, indicating how much usable energy remains. It helps in monitoring the battery's capacity and planning for recharging.

- State of Health (SOH) Assessment: The SOH assessment evaluates the overall condition and capacity of the battery. It provides insights into the battery's remaining useful life and efficiency, helping to predict potential failures and plan for replacements.

- Resistance Measurement: Measuring the internal resistance of the battery is essential, as higher resistance can indicate aging, degradation, or internal damage. Increased resistance can lead to reduced efficiency and power delivery, highlighting the need for maintenance or replacement.

These features collectively offer a comprehensive view of a deep cycle battery's status, enabling users to maintain optimal performance, anticipate issues, and ensure long-term reliability.

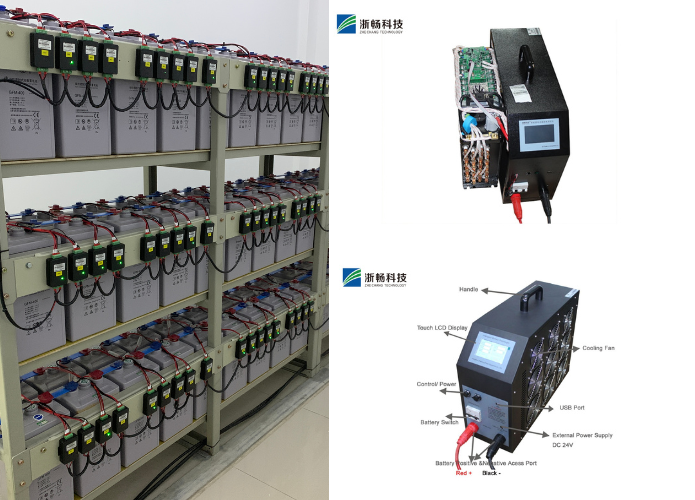

Deep Cycle Battery Analyzer

A deep cycle battery analyzer provides an in-depth and comprehensive analysis of a battery's condition, offering several key features:

- Capacity Testing: This feature measures the battery's ability to store energy, determining its actual capacity compared to its rated capacity. It helps in assessing the battery's overall health and efficiency, indicating how much charge the battery can hold and deliver over time.

- Voltage Drop Analysis: By analyzing how the voltage drops when the battery is under load, this feature assesses the battery's performance under real-world conditions. A significant voltage drop can indicate weakened or damaged cells, providing a more accurate picture of the battery's capability to deliver power.

- Diagnostic Reports: The analyzer generates detailed diagnostic reports that provide valuable information on potential issues, such as sulfation, corrosion, or internal damage. These reports often include recommended actions, such as maintenance steps or the need for battery replacement, helping users make informed decisions to maintain system reliability and performance.

These comprehensive diagnostic capabilities make deep cycle battery analyzers essential tools for monitoring, maintaining, and optimizing battery systems, ensuring they perform efficiently and reliably in various applications.

Step-by-Step Guide: How to Test a Deep Cycle Battery

Step 1: Preparation and Safety Measures

Before testing, ensure you have the necessary equipment and follow these safety precautions:

Wear protective gear, including gloves and safety glasses.

Work in a well-ventilated area to avoid inhaling harmful fumes.

Disconnect the battery from any circuits or devices.

Step 2: Using a Digital Multimeter

Set the multimeter to the DC voltage setting.

Connect the positive lead to the battery's positive terminal and the negative lead to the negative terminal.

Read the voltage and compare it to the manufacturer's specifications.

Step 3: Using a Load Tester

Connect the tester's clamps to the battery terminals, ensuring correct polarity.

Set the appropriate load for the battery type.

Observe the voltage drop and compare it to acceptable limits.

Step 4: Using a Battery Analyzer

Connect the analyzer according to the instructions.

Select the test mode (capacity, resistance, etc.).

Follow the prompts to complete the test and review the diagnostic report.

Step 5: Understanding Test Results

The data obtained from testing deep cycle batteries offer valuable insights into their condition and performance. Key parameters to consider include:

- Voltage: This parameter indicates the battery's state of charge. Monitoring voltage levels can help identify issues such as overcharging or undercharging, both of which can negatively impact the battery's lifespan. Abnormal voltage readings can also signal potential problems with the battery's internal components.

- Capacity: Capacity measurement reflects the total amount of energy the battery can store and deliver. It is an essential indicator of the battery's health and efficiency. A decrease in capacity over time may indicate degradation, which can result from factors like repeated deep discharges or aging.

- Internal Resistance: Internal resistance measures the opposition within the battery to the flow of electric current. A high internal resistance can indicate aging, damage, or deterioration of the battery's internal components. Increased resistance can lead to reduced efficiency, as it limits the battery's ability to deliver power effectively.

Together, these parameters provide a comprehensive view of the battery's overall condition, helping users detect potential issues early and take corrective actions to maintain optimal performance and extend the battery's lifespan.

Common Issues Detected by Battery Testing

Regular testing of deep cycle batteries is crucial for identifying common problems that can affect their performance and longevity. Some of these issues include:

- Sulfation: This occurs when lead sulfate crystals build up on the battery's plates, typically due to prolonged periods of low charge or incomplete charging cycles. Sulfation can significantly reduce the battery's capacity and efficiency, as the crystals inhibit the chemical reactions necessary for energy storage and delivery. Early detection through testing can allow for desulfation treatments, potentially restoring some of the lost capacity.

- Capacity Loss: Over time, all batteries experience a gradual decline in their ability to hold a charge. This loss of capacity can result from factors such as repeated deep discharges, excessive charging cycles, or exposure to extreme temperatures. Regular testing helps monitor the rate of capacity loss, enabling users to plan for replacements before the battery fails to meet power requirements.

- Physical Damage: Physical inspection as part of the testing process can reveal issues like cracks, leaks, or corrosion on the battery's terminals and casing. Such damage can compromise the battery's safety and performance, leading to potential hazards like acid leaks or electrical shorts. Detecting these issues early can prevent more severe problems and ensure the safe operation of the battery.

Maintaining Your Deep Cycle Battery

To maximize the lifespan of your deep cycle battery, following best practices is essential. Here are some key recommendations:

- Regular Charging: One of the most crucial aspects of maintaining a deep cycle battery is to avoid letting it fully discharge. Deep discharges can shorten the battery's lifespan by causing sulfation and other forms of damage. Instead, aim to recharge the battery regularly, ideally before it drops below 50% state of charge. Using a proper charging method and charger compatible with the battery type also helps maintain its health.

- Clean Terminals: Corrosion on battery terminals can lead to poor electrical connections and reduce efficiency. To prevent this, regularly inspect and clean the terminals using a mixture of baking soda and water or a specialized terminal cleaner. Ensure that the connections are tight and secure to maintain optimal conductivity. Applying a thin layer of petroleum jelly or terminal protectant can help prevent future corrosion.

- Proper Storage: When not in use, store the battery in a cool, dry place away from extreme temperatures and humidity. Extreme cold or heat can accelerate the deterioration of the battery's components. Additionally, even during storage, it's important to periodically charge the battery to maintain its charge and prevent sulfation. For long-term storage, ensure the battery is fully charged and consider using a battery maintainer to keep it at an optimal charge level.

When to Replace a Deep Cycle Battery

Despite proper maintenance, all batteries eventually reach the end of their lifespan. Here are key indicators that it may be time to replace your deep cycle battery:

Significant Capacity Loss: If the battery can no longer hold a charge effectively and the capacity has significantly diminished, it may be unable to meet the power demands of your application. This reduction in capacity is a clear sign that the battery's useful life is nearing its end.

Frequent Charging Required: If you find that the battery requires constant recharging to maintain a usable charge, it indicates that the battery's ability to retain energy has deteriorated. This symptom often accompanies increased internal resistance and reduced capacity, making the battery unreliable for continuous use.

Visible Damage: Physical signs of damage, such as cracks, bulges, or leaks, are serious concerns. These issues not only indicate that the battery's internal components may be compromised but also pose safety risks. Leaks can lead to acid exposure, while bulges suggest internal pressure buildup, both of which can be hazardous.

Conclusion

Regular testing of deep cycle batteries is crucial for maintaining their performance and extending their lifespan. Whether employing a basic multimeter or an advanced battery analyzer, understanding the current condition of your battery helps prevent unexpected failures and ensures a consistent and reliable power supply. Routine testing allows for the early detection of issues such as capacity loss, increased internal resistance, or physical damage, enabling timely interventions and maintenance.

By adhering to best practices and utilizing the appropriate testing tools, you can effectively monitor the health of your deep cycle batteries. This proactive approach not only helps in avoiding costly downtimes but also maximizes the battery's operational life. Keeping your batteries in optimal condition through regular testing and maintenance ensures they continue to deliver the power needed for your applications, whether in marine, solar, RV, or other settings, for years to come.

Popular Battery Tester

Popular Battery Tester

Latest News

Latest News

Get Price of Battery Tester

Get Price of Battery Tester

Address:

Floor 3, Building 1, No.1418-60, Moganshan road, Hangzhou city, Zhejiang Province, China.310015