How to Choose the Right Battery Testing Equipment and Machine?

Choosing the right battery testing equipment and machine is crucial for ensuring the performance, safety, and longevity of batteries across various applications. With the increasing reliance on batteries in everything from consumer electronics to electric vehicles, the importance of accurate and reliable battery testing cannot be overstated. This comprehensive guide will help you understand the different types of battery testing devices, key considerations in selecting the appropriate equipment, and best practices to ensure optimal testing outcomes.

Introduction to Battery Testing

Battery testing is an essential process that evaluates the performance, capacity, and safety of batteries. The testing process involves using specialized equipment to simulate real-world conditions, measure electrical parameters, and assess the overall health of the battery. As the demand for high-performance batteries grows, particularly in sectors like renewable energy and electric vehicles, the need for reliable battery testing equipment has become more critical.

Importance of Battery Testing

Battery testing ensures that batteries meet required standards and perform reliably under various conditions. Proper testing helps in identifying potential defects, predicting battery lifespan, and ensuring safety, particularly in high-stakes environments like aerospace, automotive, and medical devices. Battery testing equipment and machines play a vital role in this process, providing precise data that informs the development, manufacturing, and maintenance of batteries.

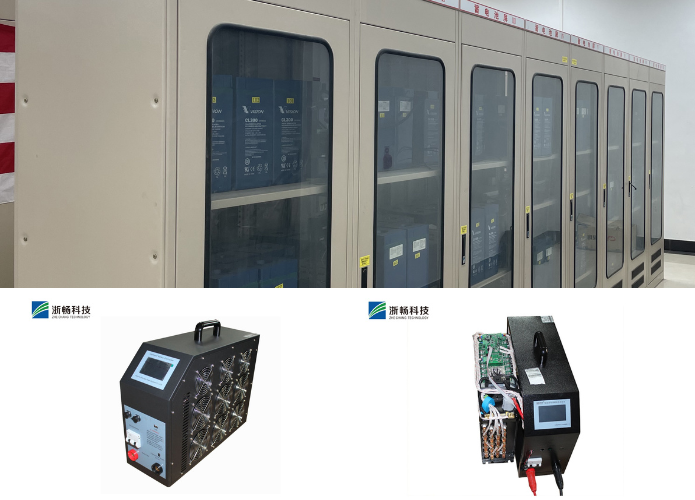

Types of Battery Testing Equipment

Understanding the different types of battery testing equipment is the first step in choosing the right tools for your specific needs. Battery testing equipment comes in various forms, each designed to perform specific tests, from basic voltage measurements to complex simulations of operating conditions.

1. Battery Analyzers

Battery analyzers are versatile testing devices used to assess various parameters such as voltage, current, resistance, and capacity. These devices are commonly used in both research and industrial settings to evaluate battery performance.

Features:

- Measure multiple parameters including voltage, internal resistance, and discharge capacity.

- Can test a wide range of battery types, including lithium-ion, lead-acid, and nickel-metal hydride.

- Often include features for data logging and analysis.

Applications:

- Ideal for routine testing of batteries in electronics, automotive, and industrial applications.

- Used in battery development labs to evaluate new battery technologies.

2. Battery Cycle Testers

Battery cycle testers simulate the charge and discharge cycles of a battery to determine its life cycle and durability. These machines are essential in assessing how a battery will perform over time under normal operating conditions.

Features:

- Capable of simulating thousands of charge-discharge cycles.

- Record data on capacity loss, cycle life, and performance degradation.

- Often programmable to mimic specific use cases.

Applications:

- Used in the development and testing of rechargeable batteries for consumer electronics.

- Essential for testing batteries used in electric vehicles and energy storage systems.

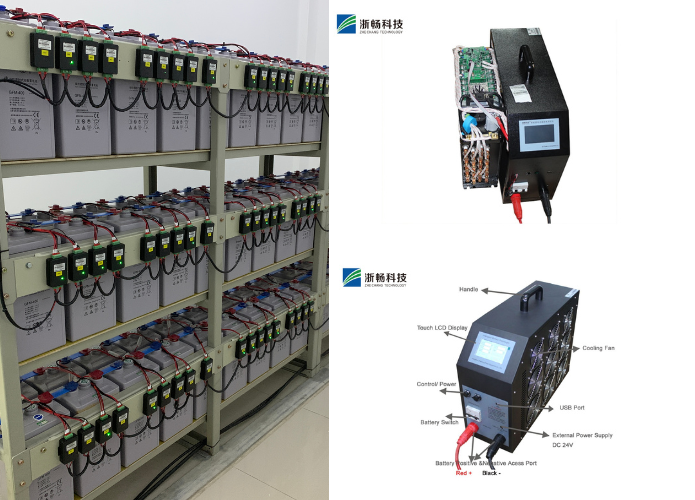

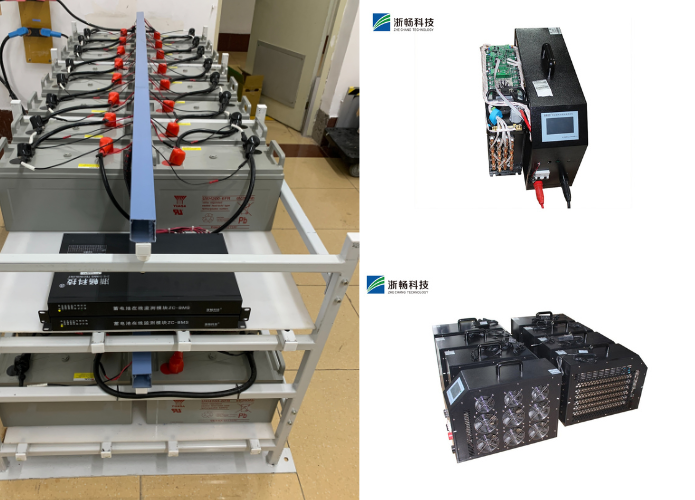

3. Battery Impedance Testers

Battery impedance testers measure the internal resistance of a battery, which is a key indicator of its health and performance. High internal resistance can lead to poor battery performance and reduced capacity.

Features:

- Provides quick and accurate measurements of battery impedance.

- Can detect issues like sulfation in lead-acid batteries or aging in lithium-ion batteries.

- Portable models available for field testing.

Applications:

- Used in maintenance and troubleshooting of batteries in critical systems like UPS and telecom networks.

- Helpful in predicting battery failure and scheduling replacements.

4. Environmental Test Chambers

Environmental test chambers are specialized machines that test batteries under various environmental conditions, such as extreme temperatures, humidity, and pressure. These tests ensure that batteries can withstand harsh operating conditions without compromising safety or performance.

Features:

- Simulate a wide range of environmental conditions.

- Can perform thermal, vibration, and humidity tests.

- Equipped with safety features to handle potential battery failures during testing.

Applications:

- Used in the automotive and aerospace industries to test batteries for extreme environments.

- Essential for ensuring the safety and reliability of batteries used in harsh conditions.

5. Battery Capacity Testers

Battery capacity testers measure the amount of charge a battery can store and deliver under specified conditions. This type of testing is crucial for determining the true capacity of a battery, which may differ from its rated capacity due to factors like age and usage.

Features:

- Provides accurate measurements of battery capacity in ampere-hours (Ah) or watt-hours (Wh).

- Can be used for single cells or entire battery packs.

- Often includes data logging and analysis features.

Applications:

- Commonly used in quality control for battery manufacturing.

- Used in maintenance checks to determine if a battery still meets its original specifications.

6. Battery Short Circuit Testers

Battery short circuit testers are designed to test a battery's ability to handle short-circuit conditions without causing catastrophic failure. These tests are critical for ensuring the safety of batteries, especially in high-power applications.

Features:

- Simulates short-circuit conditions by applying a direct short across the battery terminals.

- Monitors the battery's response, including temperature rise and potential for thermal runaway.

- Often integrated with safety features to prevent accidents during testing.

Applications:

- Used in the safety testing of batteries for consumer electronics and electric vehicles.

- Essential for compliance with international safety standards.

Key Considerations When Choosing Battery Testing Equipment

Selecting the right battery testing equipment involves considering several factors that will impact the accuracy, efficiency, and relevance of the tests you perform. Below are key considerations to keep in mind.

1. Battery Type and Chemistry

Different battery types and chemistries require specific testing methods and equipment. For instance, lithium-ion batteries have different testing requirements compared to lead-acid or nickel-metal hydride batteries. It's crucial to select battery testing devices that are compatible with the specific type of battery you are working with.

Key Points:

- Ensure the testing equipment is designed for the specific battery chemistry.

- Check if the equipment can handle the voltage and capacity range of your batteries.

- Consider equipment that can test multiple types of batteries if you work with various chemistries.

2. Testing Parameters

Battery testing can involve various parameters such as voltage, current, resistance, temperature, and capacity. The right battery testing machine should be capable of measuring all relevant parameters for your application.

Key Points:

- Identify the specific parameters you need to test.

- Choose equipment that can measure these parameters accurately and consistently.

- Consider whether the equipment allows for customizable testing protocols.

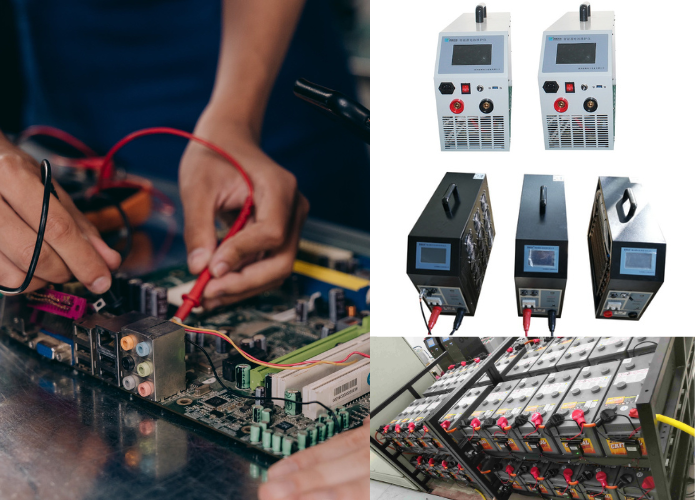

3. Accuracy and Precision

Accuracy and precision are critical in battery testing, as even small errors can lead to incorrect conclusions about battery performance and safety. High-quality battery testing devices should provide reliable and repeatable results.

Key Points:

- Check the accuracy specifications of the equipment.

- Look for equipment with built-in calibration features or services.

- Consider equipment with high-resolution measurement capabilities for better precision.

4. Data Logging and Analysis

Data logging and analysis are essential features in modern battery testing equipment. These features allow you to track battery performance over time, identify trends, and make informed decisions based on the data collected.

Key Points:

- Choose equipment with robust data logging capabilities.

- Ensure the equipment can export data in formats compatible with your analysis tools.

- Look for software that provides real-time data visualization and analysis.

5. Safety Features

Battery testing can involve handling high voltages, currents, and potentially hazardous situations, especially when testing for safety conditions like short circuits or overcharging. The testing equipment should include safety features to protect both the user and the battery.

Key Points:

- Look for equipment with built-in safety features like overcurrent protection, thermal cutoffs, and emergency stop buttons.

- Consider equipment designed to contain and manage potential battery failures safely.

- Ensure the equipment complies with relevant safety standards and certifications.

6. Ease of Use

Ease of use is an important factor, particularly if the equipment will be used frequently or by multiple operators. User-friendly interfaces, clear instructions, and straightforward setup procedures can significantly improve the efficiency of your testing processes.

Key Points:

- Choose equipment with an intuitive user interface.

- Consider whether the equipment requires specialized training to operate.

- Look for equipment that offers quick setup and easy configuration.

7. Cost and Budget Considerations

While it's important to choose high-quality equipment, it's also necessary to consider your budget. The cost of battery testing machines can vary widely based on their features, capabilities, and brand. Balancing performance with budget constraints is key.

Key Points:

- Determine your budget for battery testing equipment.

- Compare the cost of different models with similar features.

- Consider the long-term value of the equipment, including maintenance and calibration costs.

Best Practices for Using Battery Testing Equipment

Once you have selected the appropriate battery testing equipment, following best practices for its use will help ensure accurate and reliable results. These practices include proper setup, regular calibration, and safe handling procedures.

1. Proper Setup and Calibration

Proper setup and calibration of battery testing equipment are crucial for obtaining accurate results. Before starting any tests, ensure that the equipment is set up correctly and calibrated according to the manufacturer’s guidelines.

Steps:

- Follow the manufacturer’s instructions for setting up the equipment.

- Use the correct cables and connectors for your specific battery type.

- Calibrate the equipment regularly to maintain accuracy.

2. Test Planning and Execution

Effective battery testing requires careful planning and execution. This includes defining your testing objectives, selecting the appropriate test protocols, and ensuring that all necessary equipment is available and functional.

Steps:

- Define the specific goals of your battery tests (e.g., capacity measurement, cycle life testing).

- Select the appropriate test protocols based on your objectives and battery type.

- Ensure that the testing environment is controlled and consistent.

3. Data Management and Analysis

Managing and analyzing the data collected during battery testing is essential for drawing meaningful conclusions. Organizing the data, using appropriate analysis tools, and reviewing the results carefully are key steps in this process.

Steps:

- Organize data files in a systematic way for easy access and review.

- Use analysis software to interpret the data and identify trends or anomalies.

- Review the results with a focus on your specific testing objectives.

4. Safety and Handling

Battery testing can involve risks, especially when working with high-power batteries or testing for extreme conditions. Adhering to safety protocols is essential to prevent accidents and ensure the safety of personnel and equipment.

Steps:

- Follow all safety guidelines provided by the equipment manufacturer.

- Wear appropriate personal protective equipment (PPE) when handling batteries.

- Be prepared to respond to emergencies, such as battery thermal runaway or short circuits.

5. Maintenance and Calibration

Regular maintenance and calibration of battery testing equipment are critical for ensuring its long-term performance and accuracy. Establishing a routine maintenance schedule will help prevent issues and extend the life of the equipment.

Steps:

- Follow the manufacturer’s maintenance guidelines for cleaning and servicing the equipment.

- Schedule regular calibration checks to maintain measurement accuracy.

- Keep a log of maintenance activities and calibration records for reference.

Applications of Battery Testing Equipment

Battery testing equipment is used across a wide range of industries and applications, from consumer electronics to automotive, aerospace, and renewable energy. Understanding these applications can help you choose the right equipment for your specific needs.

1. Consumer Electronics

In the consumer electronics industry, battery testing is crucial for ensuring the reliability and safety of batteries used in products like smartphones, laptops, and wearable devices. Battery testing equipment helps manufacturers meet quality standards and regulatory requirements.

Applications:

- Testing battery capacity, cycle life, and safety in smartphones and laptops.

- Assessing battery performance under different environmental conditions.

- Ensuring compliance with international safety standards.

2. Automotive Industry

The automotive industry relies heavily on battery testing equipment to develop and test batteries for electric vehicles (EVs), hybrid vehicles, and conventional vehicles. The testing equipment ensures that automotive batteries meet performance, safety, and durability standards.

Applications:

- Testing the capacity, cycle life, and safety of EV batteries.

- Simulating real-world driving conditions to assess battery performance.

- Ensuring compliance with automotive industry standards.

3. Aerospace and Defense

In aerospace and defense, batteries are used in critical applications where reliability and safety are paramount. Battery testing machines are used to evaluate the performance of batteries under extreme conditions, such as high altitudes and rapid temperature changes.

Applications:

- Testing battery performance in aircraft and spacecraft.

- Assessing the reliability of batteries used in military equipment.

- Simulating extreme environmental conditions to ensure battery safety.

4. Renewable Energy Systems

Battery testing equipment is essential in the renewable energy sector, where batteries are used for energy storage in solar, wind, and other renewable energy systems. The equipment helps in evaluating the performance and lifespan of batteries used in these systems.

Applications:

- Testing the capacity and cycle life of batteries used in solar energy storage.

- Evaluating the performance of batteries under fluctuating loads.

- Ensuring the reliability of energy storage systems in remote and off-grid locations.

5. Medical Devices

In the medical field, batteries power a wide range of life-saving devices, from portable defibrillators to implantable pacemakers. Battery testing equipment ensures that these batteries are reliable and safe for use in critical medical applications.

Applications:

- Testing the longevity and safety of batteries in medical devices.

- Assessing battery performance under different usage scenarios.

- Ensuring compliance with medical device regulations.

Conclusion

Choosing the right battery testing equipment and machine is a critical step in ensuring the performance, safety, and reliability of batteries across various industries. By understanding the different types of battery testing devices, key considerations, and best practices, you can make informed decisions that will enhance your battery testing processes and outcomes.

Whether you are working in consumer electronics, automotive, aerospace, renewable energy, or any other field that relies on batteries, the right testing equipment will help you achieve your goals. Stay informed about emerging trends and advancements in battery testing to ensure that your equipment remains up-to-date and capable of meeting future challenges.

Popular Battery Tester

Popular Battery Tester

Latest News

Latest News

Get Price of Battery Tester

Get Price of Battery Tester

Address:

Floor 3, Building 1, No.1418-60, Moganshan road, Hangzhou city, Zhejiang Province, China.310015